As we get older , we learn.

Sometimes painfully, but we do learn.

I started having different brands of rifle moulds Hp'd about 20 years ago.

I felt that more ( hp pin length ) was better. As time went on and actual field testing on actual game animals was conducted, I found out........NOT SO !

A few years ago, I used a .308 Win. with 26.0 grs. of IMR 4895

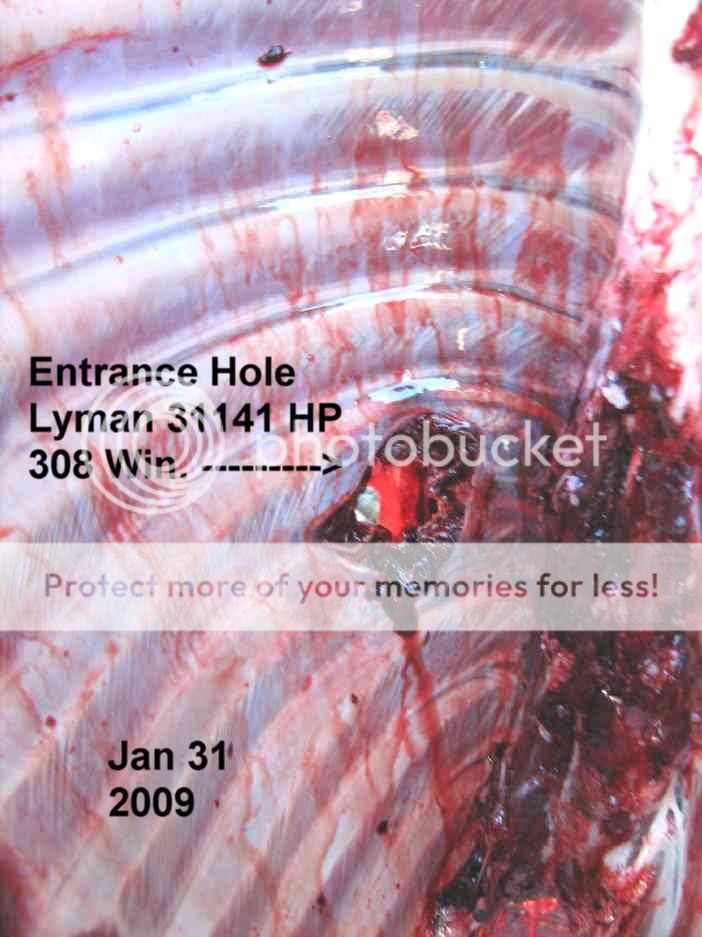

and the Lyman 31141 HP to shoot this doe. I learned a lot about

HP cast rifle bullet performance from this one event !

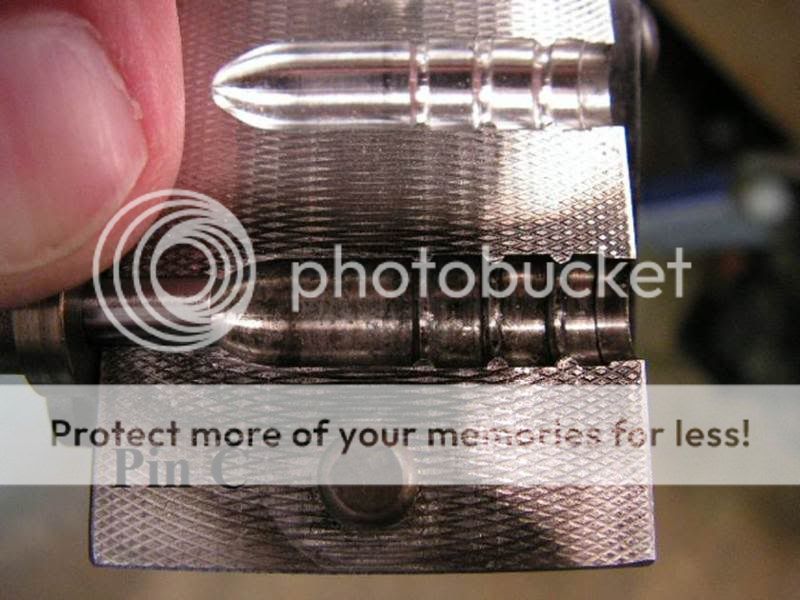

Here is a photo of the 31141 mould and the length of the HP

pin prior to me shortening the pin. This length turned out to

be far too explosive on game animals.

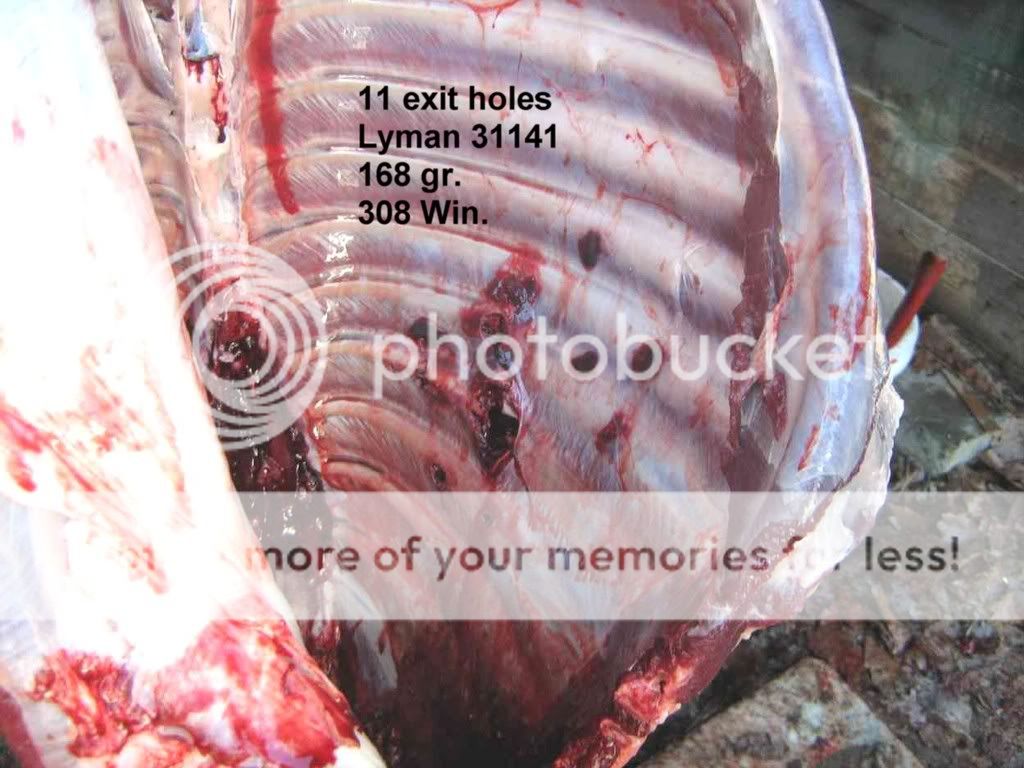

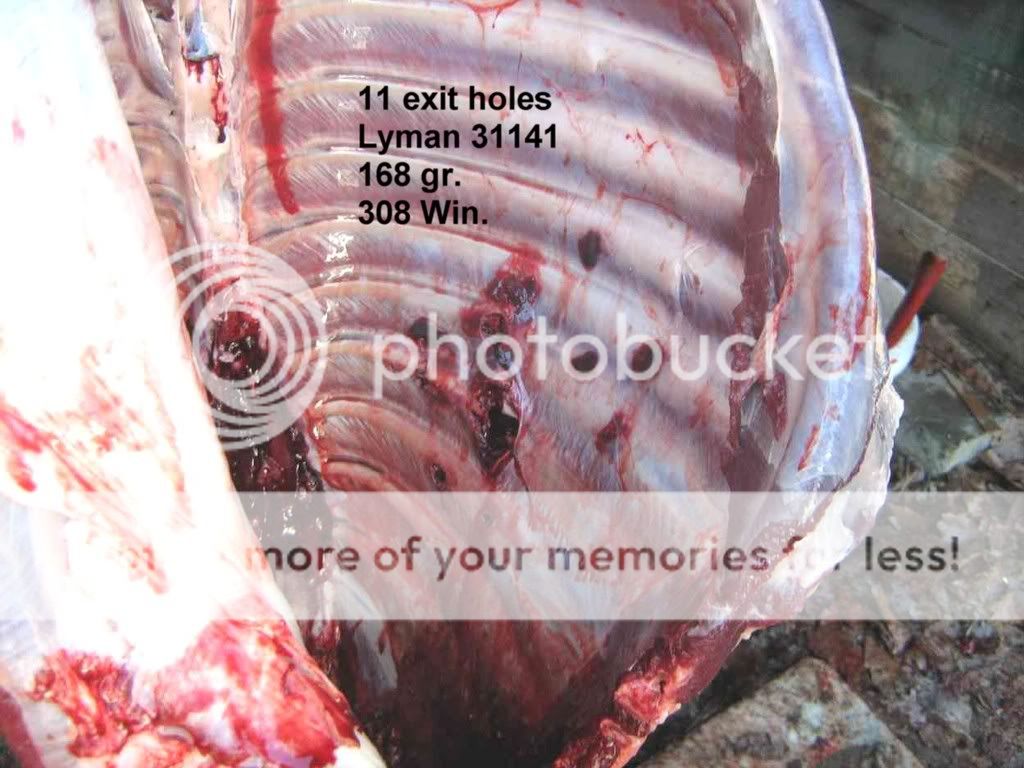

The doe had 11 exit holes . ( VERY dead deer, but not what I was looking for in cast bullet performance.)

I wanted some expansion of the nose of the bullet, but I also wanted penetration with a good exit hole.

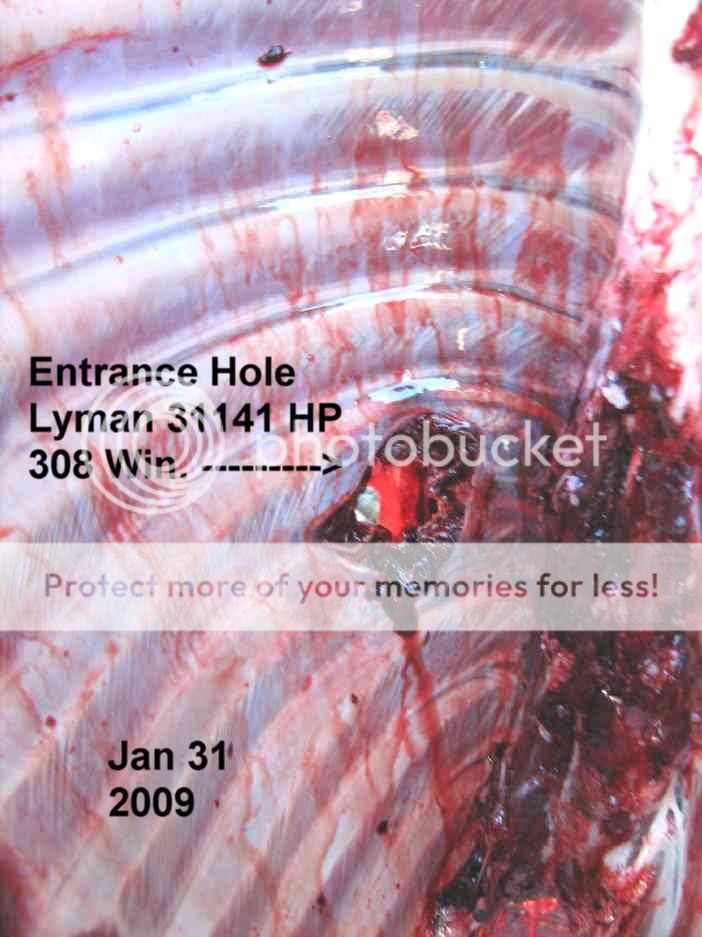

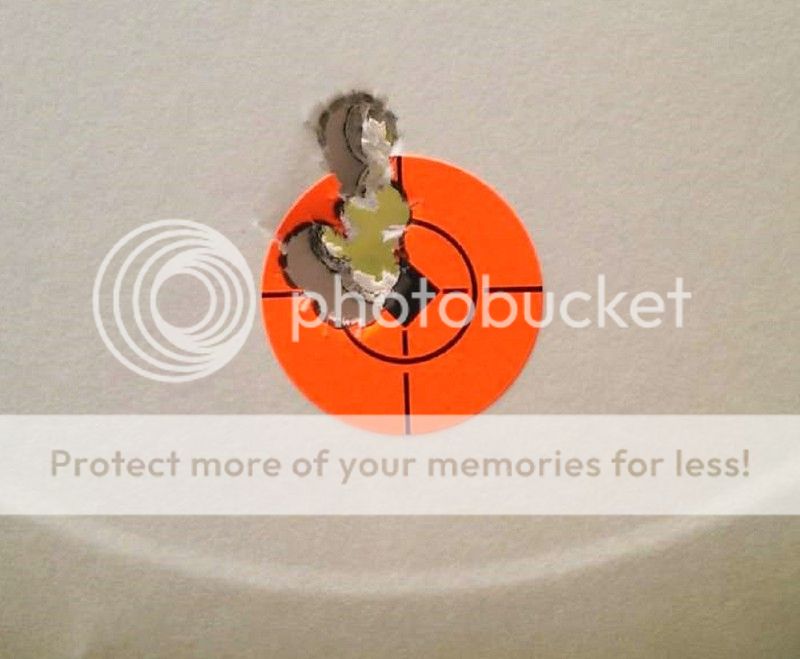

Notice this 1st photo and see how large the ENTRANCE hole is.

The bullet was expanding violently on the outside skin and ribs of the animal :

Regrettably the bullet turned out to be a flying bomb.

Several years ( and deer ) later, I've realized that IF you choose to hunt deer with cast HP bullets in the 1,800 fps velocity range, a deep HP cavity isn't your friend.

I realize that different alloys cause HP cast bullets to expand ( and penetrate ) differently.

I now use exclusively air cooled WW's for 90% of my revolver and rifle bullet casting. As a consequence, I've learned that a shallow HP cavity in the end of the nose of a .30 cal. cast rifle bullet at 1,800 fps can make a lot of difference in how the bullet behaves upon impact with a deer.

This photo below is where I am now. The HP pin may look too small and too shallow, but it isn't. At any reasonable distance, this HP cast bullet is deadly effective on white tailed deer.

Ben

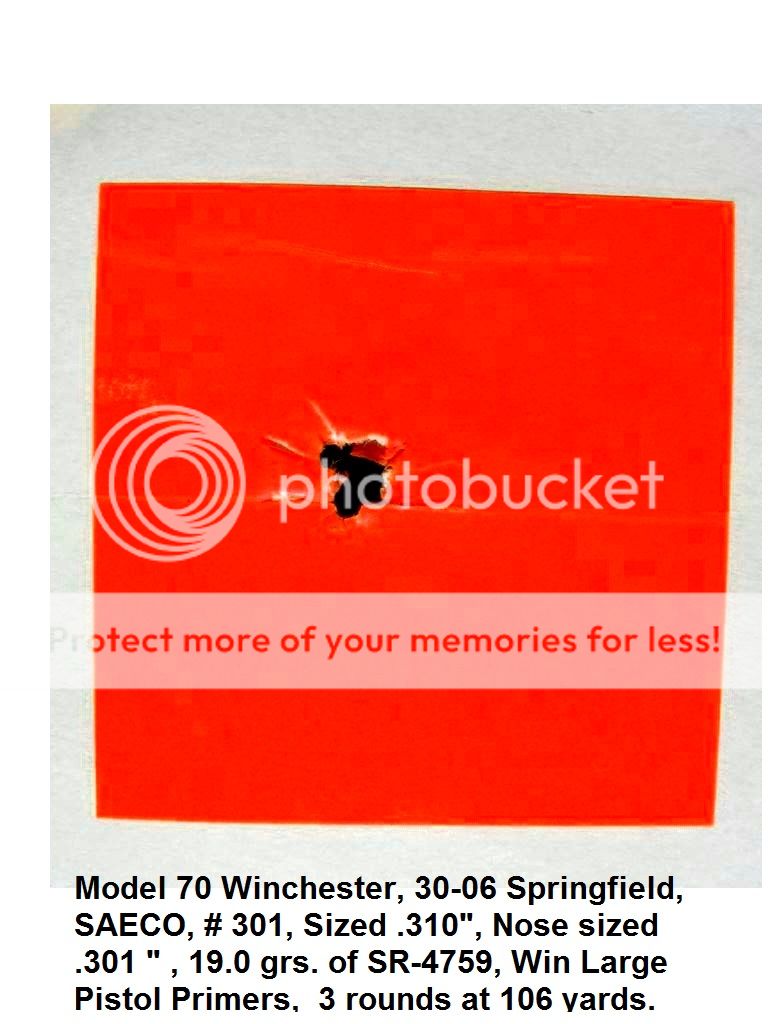

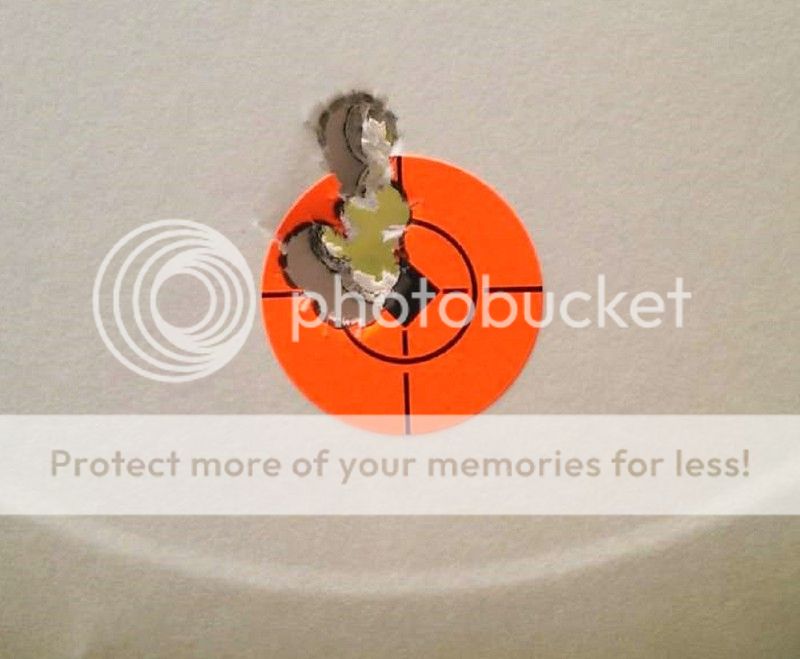

By the way, this one is plenty accurate !

The group below was fired from my Ruger # 1, 308 Win. with the same load data that I used to kill the deer above. The " high round " in the group below ( the one outside the orange paster ) is me not the rifle.

Sometimes painfully, but we do learn.

I started having different brands of rifle moulds Hp'd about 20 years ago.

I felt that more ( hp pin length ) was better. As time went on and actual field testing on actual game animals was conducted, I found out........NOT SO !

A few years ago, I used a .308 Win. with 26.0 grs. of IMR 4895

and the Lyman 31141 HP to shoot this doe. I learned a lot about

HP cast rifle bullet performance from this one event !

Here is a photo of the 31141 mould and the length of the HP

pin prior to me shortening the pin. This length turned out to

be far too explosive on game animals.

The doe had 11 exit holes . ( VERY dead deer, but not what I was looking for in cast bullet performance.)

I wanted some expansion of the nose of the bullet, but I also wanted penetration with a good exit hole.

Notice this 1st photo and see how large the ENTRANCE hole is.

The bullet was expanding violently on the outside skin and ribs of the animal :

Regrettably the bullet turned out to be a flying bomb.

Several years ( and deer ) later, I've realized that IF you choose to hunt deer with cast HP bullets in the 1,800 fps velocity range, a deep HP cavity isn't your friend.

I realize that different alloys cause HP cast bullets to expand ( and penetrate ) differently.

I now use exclusively air cooled WW's for 90% of my revolver and rifle bullet casting. As a consequence, I've learned that a shallow HP cavity in the end of the nose of a .30 cal. cast rifle bullet at 1,800 fps can make a lot of difference in how the bullet behaves upon impact with a deer.

This photo below is where I am now. The HP pin may look too small and too shallow, but it isn't. At any reasonable distance, this HP cast bullet is deadly effective on white tailed deer.

Ben

By the way, this one is plenty accurate !

The group below was fired from my Ruger # 1, 308 Win. with the same load data that I used to kill the deer above. The " high round " in the group below ( the one outside the orange paster ) is me not the rifle.

Last edited: