Barn

Active Member

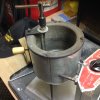

I have seen numerous comments about the flow from bottom furnaces varying with the liquid level in the pot.

I have been using an adjuster on bottom pour furnaces for many years with good results. I adjust the flow as the liquid level goes down.

I don't think this will work with a Lee. Perhaps it was my technique but I could not get consistent flows from a drip-o- matic regardless of the liquid level.

I have been using an adjuster on bottom pour furnaces for many years with good results. I adjust the flow as the liquid level goes down.

I don't think this will work with a Lee. Perhaps it was my technique but I could not get consistent flows from a drip-o- matic regardless of the liquid level.