You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

"Elvis" 61 grain in the AR 15 thread

- Thread starter Mitty38

- Start date

Mitty38

Well-Known Member

Ok, so you made a "Natural Convection" oven

Or , more precisely, as they call it , in my Industry, an "Electric Reverberator Furnace".

Pick pick pick.

But thanks,

Seriously, you have given me the means to fix my issue with stuff I have, and you have shortcut the development stage for me.

PS

Now it's time to steel the wife's oven thermometer ️

Or , more precisely, as they call it , in my Industry, an "Electric Reverberator Furnace".

Pick pick pick.

But thanks,

Seriously, you have given me the means to fix my issue with stuff I have, and you have shortcut the development stage for me.

PS

Now it's time to steel the wife's oven thermometer ️

Last edited:

Joshua

Taco Aficionado/Salish Sea Pirate/Part-Time Dragon

Convection - Wikipedia

I stand corrected, Natural Convection may very well be at work here.

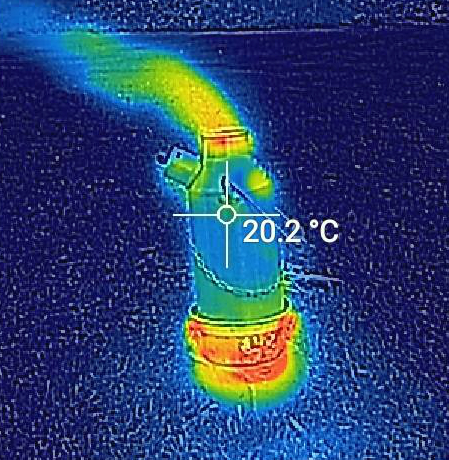

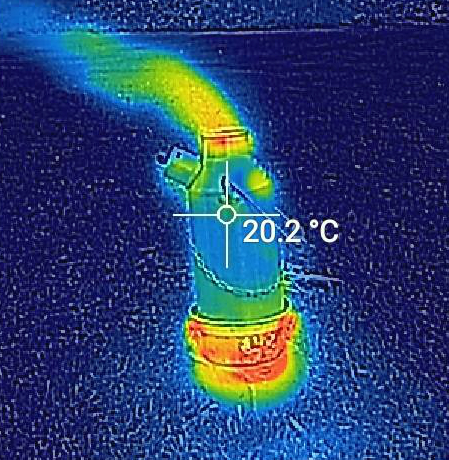

I believe by baffling the radiant heat source that heat conduction through the tile & aluminum plate has caused natural air convection, and these two forces together have equalized the the temperature in my oven.

But what do I know, I ain’t an engineer, just some guy who has built refrigeration systems, maintained boilers, built furnaces for forging steel (both venturi burners and forced air/fuel burners), forged (using coal) pattern welded Damascus steel, brazed and soldered with tin, lead, silver, and bronze, and welded (with just about every process commonly available) the following alloys, aluminum, steel, stainless, cromoly, nickel copper, copper nickel, inconel, silicon bronze, aluminum-bronze, naval brass, and copper. How’s that for a run on sentence.

Oh, and I’m ok with a cutting torch.

I’ve had some practical experience dealing with the laws of thermal dynamics.

Josh

P.s. If you spend a lifetime doing the things I’ve done for a living, you will eventually burn a hole in your underwear. It’s statistically impossible to avoid. Not all injuries are avoidable, but don’t tell the Safety Manager that! I’ve got the scar to prove it.

L Ross

Well-Known Member

Now nearing my dotage, I look back with regret at all the cool things guys like you did in your careers. Your skills developed during your working years have value in your later life. I totter out to the garage and I can't find a single azzhole to lock up.

Convection - Wikipedia

en.m.wikipedia.org

I stand corrected, Natural Convection may very well be at work here.

I believe by baffling the radiant heat source that heat conduction through the tile & aluminum plate has caused natural air convection, and these two forces together have equalized the the temperature in my oven.Pick, pick, pick

But what do I know, I ain’t an engineer, just some guy who has built refrigeration systems, maintained boilers, built furnaces for forging steel (both venturi burners and forced air/fuel burners), forged (using coal) pattern welded Damascus steel, brazed and soldered with tin, lead, silver, and bronze, and welded (with just about every process commonly available) the following alloys, aluminum, steel, stainless, cromoly, nickel copper, copper nickel, inconel, silicon bronze, aluminum-bronze, naval brass, and copper. How’s that for a run on sentence.

Oh, and I’m ok with a cutting torch.

I’ve had some practical experience dealing with the laws of thermal dynamics.

Josh

P.s. If you spend a lifetime doing the things I’ve done for a living, you will eventually burn a hole in your underwear. It’s statistically impossible to avoid. Not all injuries are avoidable, but don’t tell the Safety Manager that! I’ve got the scar to prove it.

462

California's Central Coast Amid The Insanity

Well, you did use commas.How’s that for a run on sentence.

Mitty38

Well-Known Member

I am no engineer either, just a guy who plays with molten metal. Plus a few 250k$ machines 3 to 4 days a week. One who looks at our chemist often, and says ok, when I am thinking " what did he say?".

But like you I have welded, soldered, brazed and played with metal most of my life. Even though it it was in other trades then you.

Yes I have caught my underwear on fire, but no scars. LOL

However I do occasional love a good back and forth, especially when it can be mind stretching.ᕙ( ~ . ~ )ᕗ.

But like you I have welded, soldered, brazed and played with metal most of my life. Even though it it was in other trades then you.

Yes I have caught my underwear on fire, but no scars. LOL

However I do occasional love a good back and forth, especially when it can be mind stretching.ᕙ( ~ . ~ )ᕗ.

Last edited:

Mitty38

Well-Known Member

I need a ..224 sizer. Getting measurment between . 225 and .226 on my finished bullets. I am down to the 25 best to work with they are Within .1 grain on the weight but the size is floating a bit.

Guess my project is on hold till I get one. Ordered one a couple months ago company said it was in stock. Just called them, they said it was actually out of stock and they do not know when they will get any in. Said they sent me an email, but maybe I deleted it when I was found a mass email cleaning. So the refunded me, still does not help me get my bullets sized.

Guess my project is on hold till I get one. Ordered one a couple months ago company said it was in stock. Just called them, they said it was actually out of stock and they do not know when they will get any in. Said they sent me an email, but maybe I deleted it when I was found a mass email cleaning. So the refunded me, still does not help me get my bullets sized.

Last edited:

Mitty38

Well-Known Member

Ben a little crazy round here, but managed to get 3 rounds loaded up.

17.5 grain, 2.240 OAL. ..224 diameter. Took them out to the range, just got back.

Stove pipes on all, nothing goofy looking in the barrel. 6 inch 50 yard group. Primers not even close to flatening.

It's a start.

17.5 grain, 2.240 OAL. ..224 diameter. Took them out to the range, just got back.

Stove pipes on all, nothing goofy looking in the barrel. 6 inch 50 yard group. Primers not even close to flatening.

It's a start.

18 is pretty low for H335, doesn't burn well at low density (you are ~ 1600 fps). Several OP have observed from recovered PB bullets that ball and stick powders indent the base pretty good that messes with performance. You are probably on the edge with bullet and coating dia./weight. That slick side has 1/2 -1/3 of body as drive surface that gets pulled to the base when fired. My moulds use a small groove to reduce the effect. You may get better results with a harder and smaller bullet. I push my 300 BO 145gr slick side PB pretty hard. Notices that if I cut sprue when really hard, base is slightly crooked. I got a circular pattern at 100, still almost MOA. I have a 22lr so no desire or need for 223.

Last edited:

Dimner

Named Man

18 is pretty low for H335, doesn't burn well at low density (you are ~ 1600 fps). Several OP have observed from recovered PB bullets that ball and stick powders indent the base pretty good that messes with performance. You are probably on the edge with bullet and coating dia./weight. That slick side has 1/2 -1/3 of body as drive surface that gets pulled to the base when fired. My moulds use a small groove to reduce the effect. You may get better results with a harder and smaller bullet. I push my 300 BO 145gr slick side PB pretty hard. Notices that if I cut sprue when really hard, base is slightly crooked. I got a circular pattern at 100, still almost MOA. I have a 22lr so no desire or need for 223.

I have experienced this with H335 and Ramshot TAC. Also another issue with using these types of powder at a low density is carbon fouling. I got a whole heck of alot. Made it so I had to clean out the carbon every 100-150 rounds. That's when I moved to other powders.

CWLONGSHOT

Well-Known Member

Sorry just seeing this now.I need a ..224 sizer. Getting measurment between . 225 and .226 on my finished bullets. I am down to the 25 best to work with they are Within .1 grain on the weight but the size is floating a bit.

Guess my project is on hold till I get one. Ordered one a couple months ago company said it was in stock. Just called them, they said it was actually out of stock and they do not know when they will get any in. Said they sent me an email, but maybe I deleted it when I was found a mass email cleaning. So the refunded me, still does not help me get my bullets sized.

I have a 224 LEE

Mitty38

Well-Known Member

That's fine, I am in no hurry at the moment, Spring is here and got a lot of pans in the fire.Sorry just seeing this now.

I have a 224 LEE

Anyhow, looks like I am going to have to give up my AR. So not getting too excited about finishing this load for it, at the moment. So this will probably end up being a bolt action load.

Just can not afford to pay whatever tax that will be slapped on AR15's. If they are not made illegal all together.

Not being political, just realistic.

Not putting good money and time after bad.

It will just be something I am piddling with, with what I have, till we see what the near future holds.

Last edited:

CWLONGSHOT

Well-Known Member

Sorry to read that.

Remember, no one can write a executive order to circumvent the Constitution.

I like to be prepaired, but this situation, Ill deal with if it becomes something requiring that. IMHO a whole lotta bad is gonna be involved if that tac is attempted.

In any event that .224 LEE sizer isnt used as I use my .225 NOE.

CW

Remember, no one can write a executive order to circumvent the Constitution.

I like to be prepaired, but this situation, Ill deal with if it becomes something requiring that. IMHO a whole lotta bad is gonna be involved if that tac is attempted.

In any event that .224 LEE sizer isnt used as I use my .225 NOE.

CW

Mitty38

Well-Known Member

PM me let me know what you want for it. Or what you had in mind, a lone,trade?Sorry to read that.

Remember, no one can write a executive order to circumvent the Constitution.

I like to be prepaired, but this situation, Ill deal with if it becomes something requiring that. IMHO a whole lotta bad is gonna be involved if that tac is attempted.

In any event that .224 LEE sizer isnt used as I use my .225 NOE.

CW

I could still use it even if I went bolt later, can always hone it out a bit, just can not make them smaller.