Air pocket behind the tip lets it get moving before it hits the lead. Else it's just a hard tip. Black tip Cu solids are good for long range shooting (pigs mostly), Gdot (150 especially made for BO) are giving good expansion but still super fps. Trying my softening experiment again, like 2% Sb H.T. RD 170 gr. Set the base on hot plate for count of 10 and 20, will test next week for softening ( vise squease test - soften the base as the bands are parrallel). These do feed through my BO pistol. I did test the RD with 1% Sb on pig carcass and got expansion but not much accuracy. Another approach I've heard of is the Al. foil in the nose for a split nose. Did find a ballistic calc (excel) the will give drop for different bullets for MY scope setting. Still have an inch diff unaccounted for.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Getting started with the 300blk ...

- Thread starter wquiles

- Start date

Tested the 'test' today. 20 count are softer in the base, 10 - no difference. Will test again next week as IMHO the alloy will harden over time. IIRC Fullleadtaco has some vids of his super heavy sub from pistol that did pretty well. I thought about getting a brace for mine but next time sombody uses an AR pistol with brace it's money down the drain. Same kinda thing with a can.

wquiles

Well-Known Member

Modified the seating die and created a new flat tip insert for the die (drill rod since that is what I had on hand):

Created my first complete 300bkl dummy round

Per UPS the lower receiver should arrive tomorrow afternoon, so maybe Tue I can pick it up and start working on it

Created my first complete 300bkl dummy round

Per UPS the lower receiver should arrive tomorrow afternoon, so maybe Tue I can pick it up and start working on it

Repeated 'test' test today, still seem to have soft base. Ref had parallel indention, test has non-parallel, ~10deg angle. If this works I'll stand them up in my 'alignment' fixture, place a heated ceramic tile on the noses for proper count and wait a week to shoot them. Kinda like the flame on the nose trick which will burn the PC. Should give hard drive bands and softer nose.

Ian

Notorious member

Looks good Will. I put a little touch of roll crimp on mine, helps them feed.

How did you check alignment? I believe your last photo in post 45 got out of place, at least that's how the forum software is putting it up for me (sometimes photos display in the wrong places temporarily).

How did you check alignment? I believe your last photo in post 45 got out of place, at least that's how the forum software is putting it up for me (sometimes photos display in the wrong places temporarily).

wquiles

Well-Known Member

I am planning on using the Lee FCD to help them feed properly. This is the very first time I am reloading for the ar15, so all new to me in what will work or not. Part of the learning curve for me.Looks good Will. I put a little touch of roll crimp on mine, helps them feed.

How did you check alignment? I believe your last photo in post 45 got out of place, at least that's how the forum software is putting it up for me (sometimes photos display in the wrong places temporarily).

I fixed the photo. Sorry about that (yes, sometimes the forum software messes up, but this time it was "me"!).

For alignment check, I did it optically. I removed the bolt, and look through the barrel at a bright area and move around to see if I can pick-up the edge(s) of the end cap on the suppressor. I am pretty anal about this alignment work on the lathe, and it is not that I "expect" it to be a problem, but I always like to do this visual check when installing a suppressor for the first time, and even more so since I got the stacking on the tolerances of 3 components:

- the barrel threads and edge (which I didn't machine), plus

- the taper suppressor mount (that I machined) plus

- the complete F1 308 suppressor which is about 9 inches (which I machined).

Gives me a warm feeling when I can see everything nice and aligned before taking the first shot

On other forums I know some buy straight steel rods of various sizes, which then get inserted (gently) in the barrel to check concentricity, etc., but I hate to touch the potentially delicate crown on a barrel.

By the way, still on the 300bkl - you mentioned that at about 5" of barrel travel I should look for loads in QL that would give me at least 6K PSI for cycling the bolt. How about on the max. side? As long as cartridge-wise I am safe and under the SAAMI limits, do I need to worry about the port pressure for the higher-end supersonic loads?

Will

Last edited:

Ian

Notorious member

6K+ at the port, wherever that is for you. 7K is better. Remember QL figures distance from the base of the bullet on the pressure/distance graph. For supers, it will be overgassed UNLESS you make some compromises and use a powder that gets it mostly done before the port and is dropping off likewise at 6-10K PSI at the port. The compromise means ultimate velocity at the top end vs. having to adjust something when switching back and forth to subsonic ammunition. Usually you can build loads to optimize the system you have and not have to change the pistol's gas between the two. Slow powders like 4198 for heavy subs and faster powders like H110 for lightweight supers is typical. The BLK was specifically designed to operate in its full range of use without any gas adjustments, but most BLK uppers are not built to AAC's original design specs for gas port location or size (because most people in the consumer market aren't running suppressors, for one thing and AAC designed for jax bullet engraving pressure is another) and so you may have to play a bit with powders and bullet weight to make what you have work well at both ends.

Don't forget, gas needs will change as the upper breaks in, and it's always a good idea to polish the inside of the buffer tube and put a JP extra-power, polished spring in there to help the bolt push home those heavyweight subsonics. In other words, if you get failures to go into fully into battery and failure to lock back on the last round, up the powder charge a little but be prepared to cut back after a few hundred rounds. You want some extra margin for running dirty (it WILL get filthy with the suppressor) but not more margin than you absolutely need (gas face, excess port noise, etc.).

Don't forget, gas needs will change as the upper breaks in, and it's always a good idea to polish the inside of the buffer tube and put a JP extra-power, polished spring in there to help the bolt push home those heavyweight subsonics. In other words, if you get failures to go into fully into battery and failure to lock back on the last round, up the powder charge a little but be prepared to cut back after a few hundred rounds. You want some extra margin for running dirty (it WILL get filthy with the suppressor) but not more margin than you absolutely need (gas face, excess port noise, etc.).

Last edited:

I use the FCD, no problem with chambering due to flare. Push down to just hard resistance on the press handle. My 10" pistol dumps cases @ 5oclock on supers with a H2 buffer. AGB that is stuck about half open. Loads that run >2k fps in carbine so probably 1700 in the pistol. With a can you get pressure much longer. Anything with normal BO powders it will cycle. With 100gr plinkers and the gas turned all on, CFE pistol wouldn't quite cycle. I'm jealous of you guys with the machine tools.

Ian

Notorious member

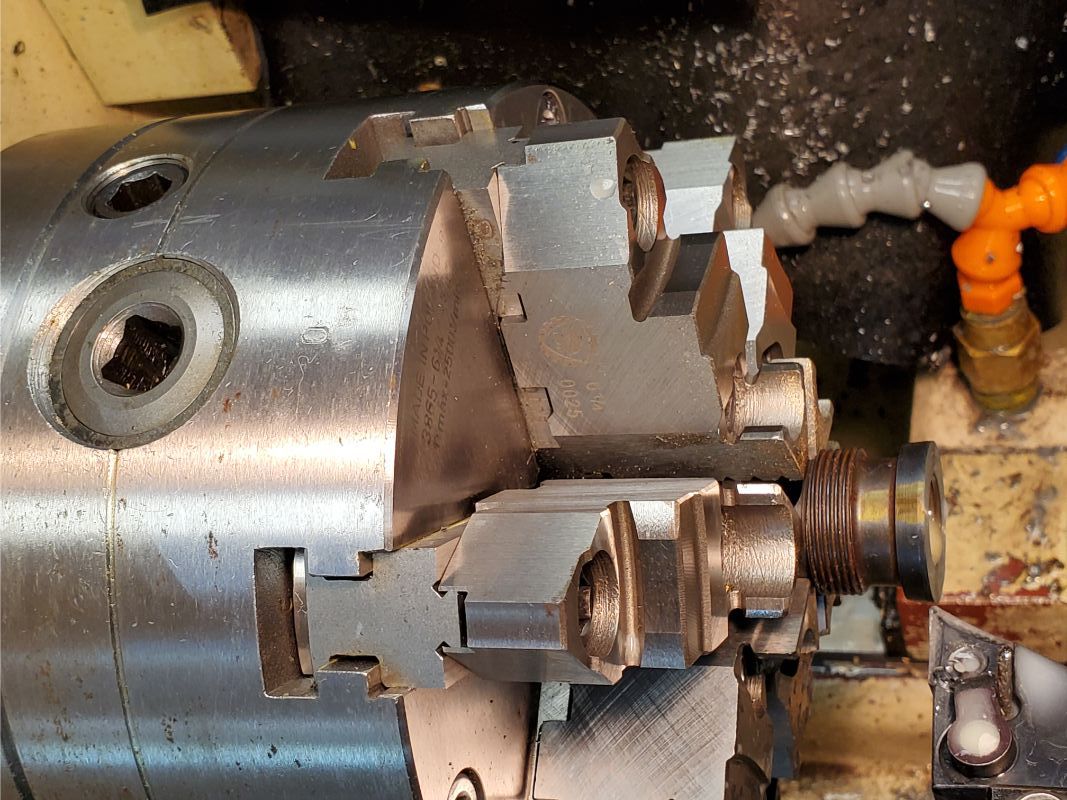

Speaking of machine tools, if you want to make the Lee FCD REALLY kick a$$, do the following mod:

Pull the collet out of the die and use a worm-gear hose clamp to cinch the fingers completely closed. Chuck the opposite end in your 6-jaw (or 4-Jaw) and bump or adjust until the hole in the crimping end runs absolutely true. Put a chainsaw sharpening stone or similar cylindrical diamond burr in your toolpost grinder at about 2-4° off-axis and grind a VERY slight cone on the back side of the crimp "jaws", fading it to nothing on the outermost part so it's not enlarged at all. A 5-8° included angle is good.

This will swage a taper crimp on your ammo, much preferable to the parallel crimp because it won't work the necks as badly and will help you get the mouth tucked for best feeding. If you don't have a tool post grinder, clamp your Dremel to your toolpost and use that (it's what I do on my mini-lathe). If you find your brass trim length and the collet length aren't coinciding for a full crimp, you can grind the base of the collet or make a shim cup for your shellholder (like a big, upside-down gas check with a U-notch to match the shellholder to adapt as necessary.

Pull the collet out of the die and use a worm-gear hose clamp to cinch the fingers completely closed. Chuck the opposite end in your 6-jaw (or 4-Jaw) and bump or adjust until the hole in the crimping end runs absolutely true. Put a chainsaw sharpening stone or similar cylindrical diamond burr in your toolpost grinder at about 2-4° off-axis and grind a VERY slight cone on the back side of the crimp "jaws", fading it to nothing on the outermost part so it's not enlarged at all. A 5-8° included angle is good.

This will swage a taper crimp on your ammo, much preferable to the parallel crimp because it won't work the necks as badly and will help you get the mouth tucked for best feeding. If you don't have a tool post grinder, clamp your Dremel to your toolpost and use that (it's what I do on my mini-lathe). If you find your brass trim length and the collet length aren't coinciding for a full crimp, you can grind the base of the collet or make a shim cup for your shellholder (like a big, upside-down gas check with a U-notch to match the shellholder to adapt as necessary.

Last edited:

wquiles

Well-Known Member

Thanks much Ian. I have been playing with QL a little already, and noticed the PSI differences between a couple of powders, which is where my question comes from. Your explanation helps a lot put everything together now. I didn't know about the JP extra power spring - nice to know as well.6K+ at the port, wherever that is for you. 7K is better. Remember QL figures distance from the base of the bullet on the pressure/distance graph. For supers, it will be overgassed UNLESS you make some compromises and use a powder that gets it mostly done before the port and is dropping off likewise at 6-10K PSI at the port. The compromise means ultimate velocity at the top end vs. having to adjust something when switching back and forth to subsonic ammunition. Usually you can build loads to optimize the system you have and not have to change the pistol's gas between the two. Slow powders like 4198 for heavy subs and faster powders like H110 for lightweight supers is typical. The BLK was specifically designed to operate in its full range of use without any gas adjustments, but most BLK uppers are not built to AAC's original design specs for gas port location or size (because most people in the consumer market aren't running suppressors, for one thing and AAC designed for jax bullet engraving pressure is another) and so you may have to play a bit with powders and bullet weight to make what you have work well at both ends.

Don't forget, gas needs will change as the upper breaks in, and it's always a good idea to polish the inside of the buffer tube and put a JP extra-power, polished spring in there to help the bolt push home those heavyweight subsonics. In other words, if you get failures to go into fully into battery and failure to lock back on the last round, up the powder charge a little but be prepared to cut back after a few hundred rounds. You want some extra margin for running dirty (it WILL get filthy with the suppressor) but not more margin than you absolutely need (gas face, excess port noise, etc.).

This is a really nice idea. I like the "concept" of the Lee FCD but not the execution, for the same reasons you mentioned. Turning it into a more gentle taper is awesome. Definitely another project to try out this coming weekendSpeaking of machine tools, if you want to make the Lee FCD REALLY kick a$$, do the following mod:

Pull the collet out of the die and use a worm-gear hose clamp to cinch the fingers completely closed. Chuck the opposite end in your 6-jaw (or 4-Jaw) and bump or adjust until the hole in the crimping end runs absolutely true. Put a chainsaw sharpening stone or similar cylindrical diamond burr in your toolpost grinder at about 2-4° off-axis and grind a VERY slight cone on the back side of the crimp "jaws", fading it to nothing on the outermost part so it's not enlarged at all. A 5-8° included angle is good.

This will swage a taper crimp on your ammo, much preferable to the parallel crimp because it won't work the necks as badly and will help you get the mouth tucked for best feeding. If you don't have a tool post grinder, clamp your Dremel to your toolpost and use that (it's what I do on my mini-lathe). If you find your brass trim length and the collet length aren't coinciding for a full crimp, you can grind the base of the collet or make a shim cup for your shellholder (like a big, upside-down gas check with a U-notch to match the shellholder to adapt as necessary.

Will

OK, 'test' is working. Same indentation pattern, a 'V' wider at the base. Basically grooveless with drive band 70% of length (0.88" long bullet). Sized 311 after PC. 20 sec heating of the base and it stays soft (AC). 2% Sb with a tad of Cu. So I can H.T. after PC, line them up in my holder, set a hot ceramic tile on the noses and get hard band/soft nose bullets. It's PB, I'll try in the 30/30 first. Also try some iso-core alloy. Final results prob. in Aug.

wquiles

Well-Known Member

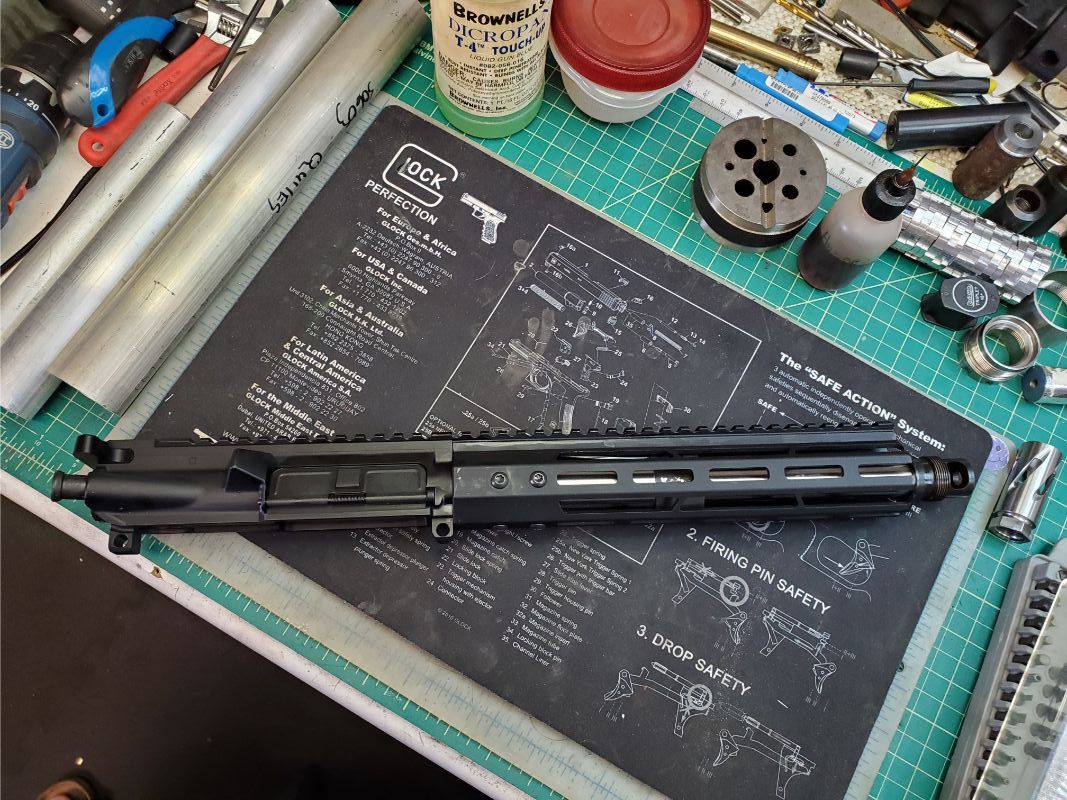

OK, receiver picked up on Tuesday as I hoped:

This was my second ever stripped receiver build, first one being 20+ years ago, early Internet days - so no youtube videos, or photo by photo posts in forums on how to assemble: I used a physical book last time

This time, of course, I found a good step-by-step post with close-up pictures, and I had it built in no time:

I "love" how light and fast handling it feels. Really awesome!

This was my second ever stripped receiver build, first one being 20+ years ago, early Internet days - so no youtube videos, or photo by photo posts in forums on how to assemble: I used a physical book last time

This time, of course, I found a good step-by-step post with close-up pictures, and I had it built in no time:

I "love" how light and fast handling it feels. Really awesome!

wquiles

Well-Known Member

Now, I wanted to start loading some supersonics using the NOE 311-122-FN-J4 4 cavity GC (311-122-FN-J4-60):

I started assembling some dummies to check for loading, magazine fit, etc, but the nose is so freaking wide that I have to keep making them freaking short in order not to jam into the rifling when the bolt closes:

The GOOD news is that every single time I closed the bolt every bullet loaded in my rifle, so no problem with the relatively "flat" point. But I am a little worried on how short they ended up. I painted the tips with a black Sharpie so that I can "see" better where and how they hit on the feed ramp/barrel:

Any problems with those "short" bullets in that PMAG magazine? Should I be concerned with the 1.665" COL? Or OK to start loading some with powder/primers to test out at the range?

Will

I started assembling some dummies to check for loading, magazine fit, etc, but the nose is so freaking wide that I have to keep making them freaking short in order not to jam into the rifling when the bolt closes:

The GOOD news is that every single time I closed the bolt every bullet loaded in my rifle, so no problem with the relatively "flat" point. But I am a little worried on how short they ended up. I painted the tips with a black Sharpie so that I can "see" better where and how they hit on the feed ramp/barrel:

Any problems with those "short" bullets in that PMAG magazine? Should I be concerned with the 1.665" COL? Or OK to start loading some with powder/primers to test out at the range?

Will

Ian

Notorious member

Try and see. I personally don't like to see that much space at thr front of the magazine because cartridges can work forward under recoil and cause the dreaded double-feed. That said, I had 100% reliable feeding of the first four out of five and about 50% of feeding the last .45 ACP out of an unmodified 5.56 pmag in my DI-45, and there was a LOT of room in front of those.

I highly recommend making a two-diameter nose and body bullet sizing die with a tapered transition between the two sizes that matches your throat taper. In/out and the noses are uniformed and trued with the driving bands. Make an ejector and ejector bar for your awesome homemade press and crank them out.

I highly recommend making a two-diameter nose and body bullet sizing die with a tapered transition between the two sizes that matches your throat taper. In/out and the noses are uniformed and trued with the driving bands. Make an ejector and ejector bar for your awesome homemade press and crank them out.

I'm using 142c, 182c noses fit ok but loaded deep you will get the overrun feed problem. You also have to watch the rims, torn up and they strip the lower one.

My throat is about half the neck length, then a quick taper to bore. You red may not feed or chamber. Plunk test yet?

My throat is about half the neck length, then a quick taper to bore. You red may not feed or chamber. Plunk test yet?

Last edited: