Snakeoil

Well-Known Member

My shooting partner bought this mold new and it turned out he really did not need a bigger bullet in his rifle. So, he has no used for it.

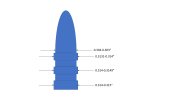

This is the NOE version of the Lyman 214299 bullet. This the GC version this bullet in my 03 Springfield with great success. I would have taken the mold if I did not already own a 4 cavity version.

The mold is out of stock (what's new) at NOE but lists for $118.25. With shipping it would be $131.45 based upon 2020 shipping prices. Not sure if NOE is charging tax yet. There was no tax on my last mold purchase back in 2020.

Mold is in great shape. Steve smokes his molds and I cleaned it up. But the smoke is why it looks a little stained in places. I've never needed to smoke an NOE mold. Somebody told Steve to smoke his molds so he's always done it. I told it is not necessary.

$110 shipped anywhere in the US.

This is the NOE version of the Lyman 214299 bullet. This the GC version this bullet in my 03 Springfield with great success. I would have taken the mold if I did not already own a 4 cavity version.

The mold is out of stock (what's new) at NOE but lists for $118.25. With shipping it would be $131.45 based upon 2020 shipping prices. Not sure if NOE is charging tax yet. There was no tax on my last mold purchase back in 2020.

Mold is in great shape. Steve smokes his molds and I cleaned it up. But the smoke is why it looks a little stained in places. I've never needed to smoke an NOE mold. Somebody told Steve to smoke his molds so he's always done it. I told it is not necessary.

$110 shipped anywhere in the US.