Josh

Well-Known Member

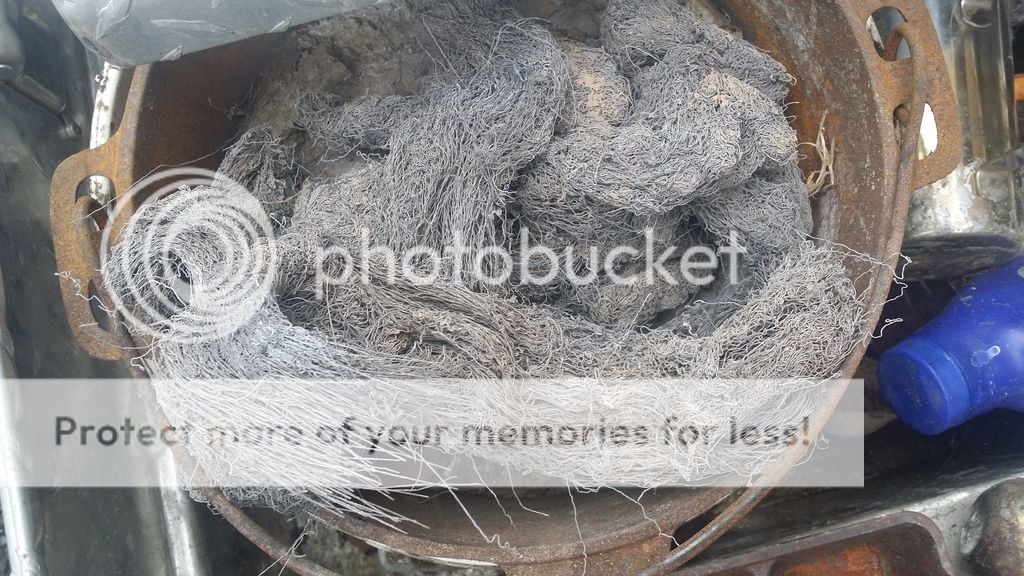

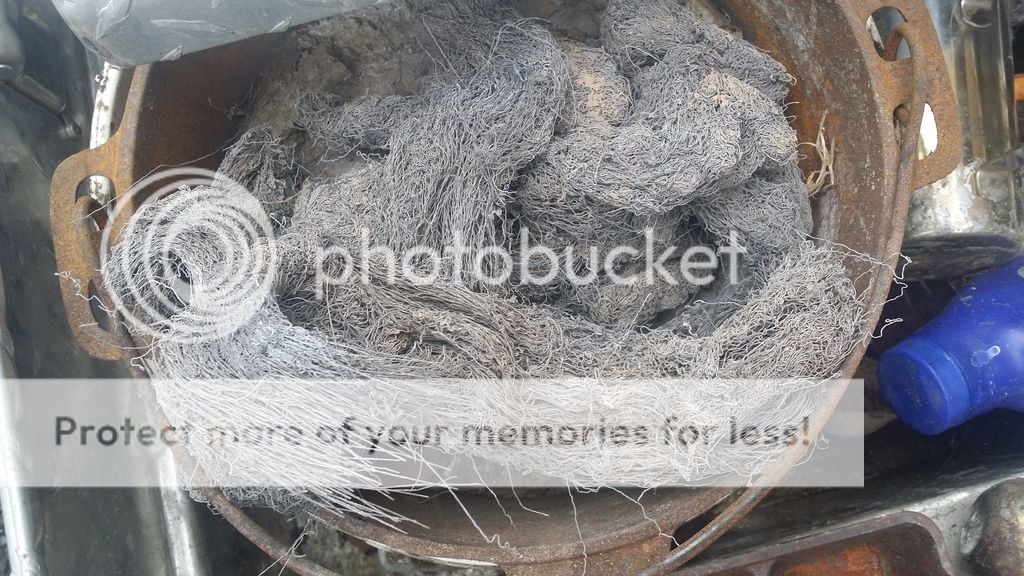

I came across a thousand pounds of electric conduit, it is 1/4 inch thick pipe about 3" in diameter and stuffed full of this stuff:

It seems to be lead as it melts but I have no clue what kind of lead it is, I got it all for free just for picking it up. Anyone know what alloy it is?

Thanks!

Josh

It seems to be lead as it melts but I have no clue what kind of lead it is, I got it all for free just for picking it up. Anyone know what alloy it is?

Thanks!

Josh

Last edited: