As I understand the function, you are trying to strip the gases off of the projectile, divert them

to the sides, and let them expand there. Seems like you want as many different "wipes" (incorrect

usage, since I think a real wipe actually touches the bullet), maybe it should be called "bullet scraper"

or "diaphragm", but you want many chances for the pressure to drop across a closely fitted feature.

Have you ever seen the seals on a gas turbine? The have high pressure gases inside and a rotating

shaft, and want to keep the gases in but not touch the shaft, mostly because it is running at 90,000 rpms

or so. They have what is called a labyrinth seal, just a series of tightly fitted, not touching, diaphragms.

Each one has a certain amount of leakage due to the small radial gap to the shaft, but causes a big

pressure drop. Put a dozen in a row and each dropping the pressure a bunch below the previous one

and the end pressure is quite low. Seems not unlike a suppressor, except you have to store a large

quantity of gas inside the suppressor, and expand and cool it. So, each diaphragm needs a larger

storage annulus radially outward from it.

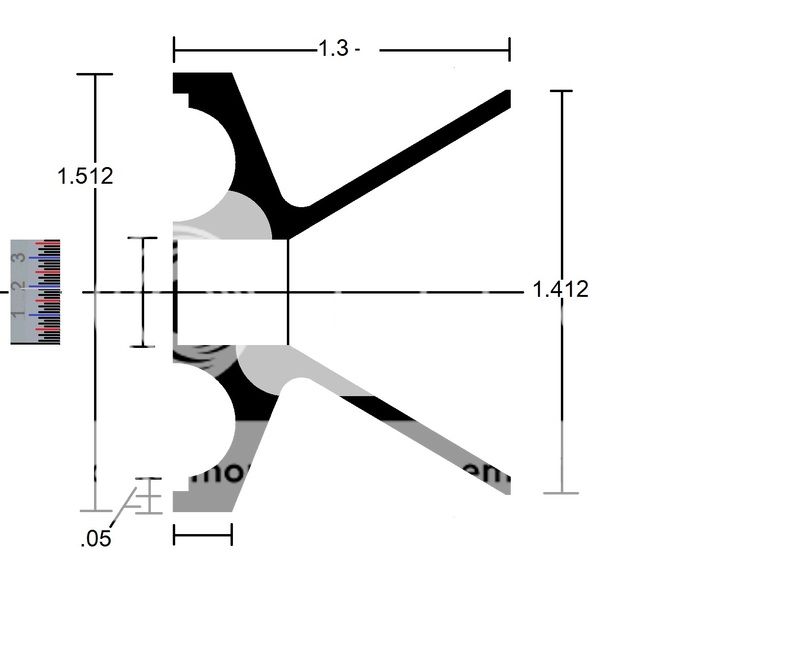

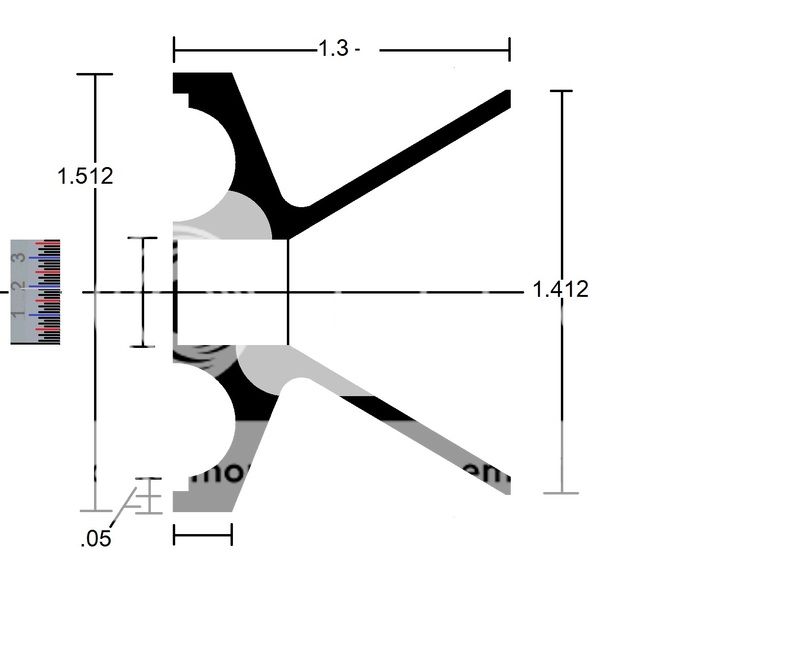

Back to your design. You get another pressure drop diaphragm, but little storage volume for it. Not

sure of the trade off. I think that since a suppressor deals with flow where a diaphragm seal does not

deal with much flow, the angled diaphragm to redirect the flowing gases outward is a plus over a flat

one.

Another factor in suppressor baffles is the huge pressure shock that the baffles are subjected to. Just

because it is nice for gas flow, it may be useless if the hammer blow of gas pressure mechanically

destroys it on the first shot, or more likely, causes it to crack after a few hundred shots. So, mechanical

strength is definitely on the table. Then for full auto or rapid fire semi auto..... it's gonna get real hot.

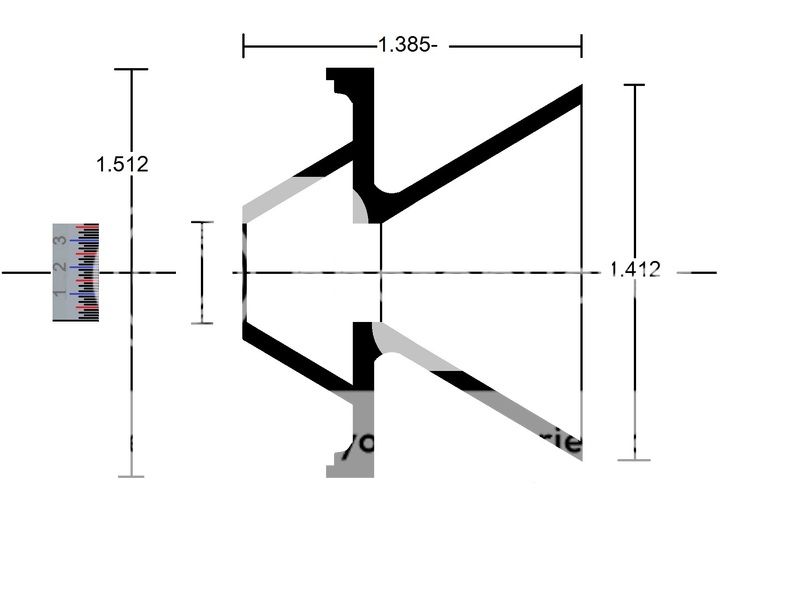

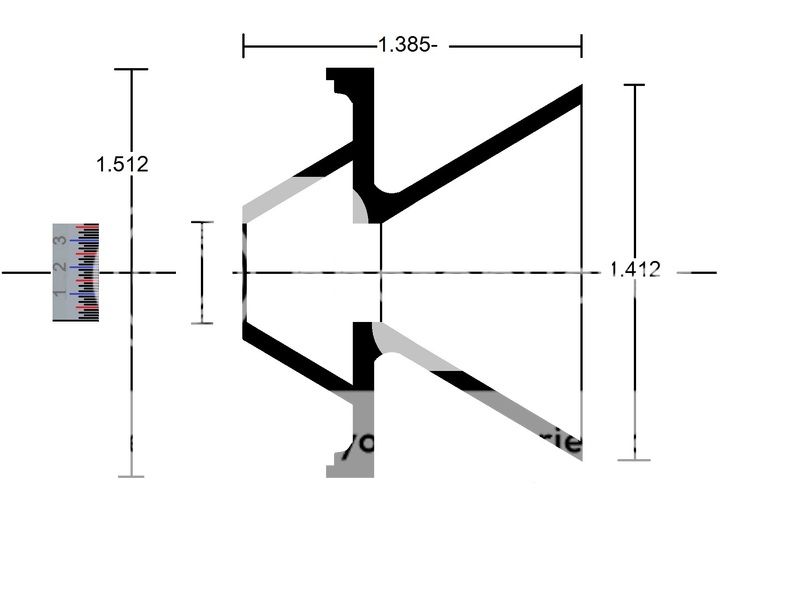

The new one looks mechanically strong, adds a diaphragm and some expansion, but not much. I wonder if

venting the small new cavity outward with holes would help let more gases flow out radially?

All theoretical conjecture. I assume you have the correct paperwork to make this stuff, the folks at BATF

are meaner than a snake, would not want to get crosswise with them. It is so fundamentally stupid that this

stuff is illegal without proper gov't blessing. In NZ they are hardware store items, not unlike a hammer or

chain saw.

Bill