CWLONGSHOT

Well-Known Member

Am I the only one with OUTSIDE deburring issues??

I have use "spaceships" and the LEE and Lyman tools for years as well.

The lee is actually nicest if it was just a bit more agressive.

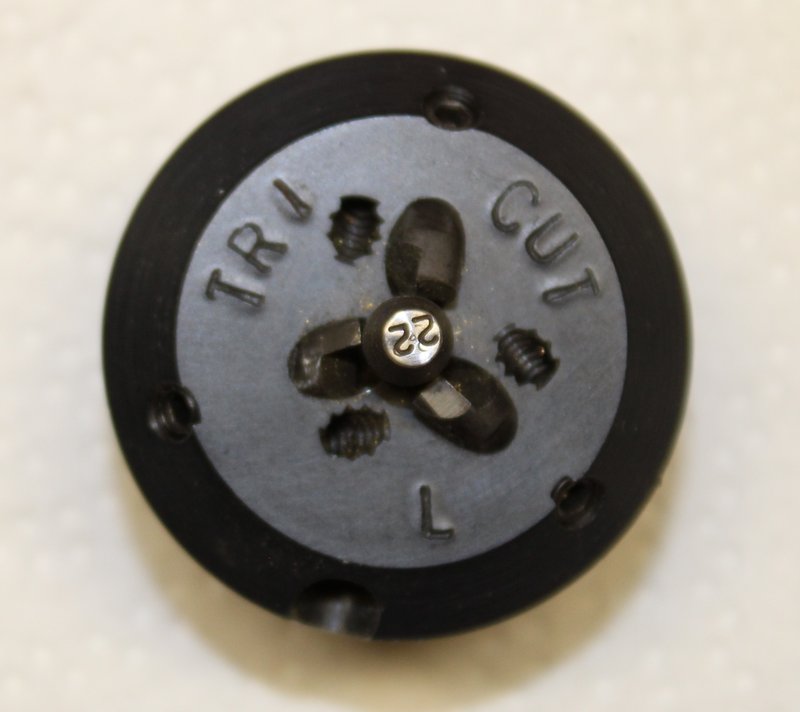

I was looking thru a fellas stuff last few days. (Sorting out for sale) and he had a Frankfort Arsenal case prep machine and a RCBS machine. The RCBS had a tool I had not seem. There was a Long tapered inside debur tool and a "cup looking" tool similar to that LEE but different. Searching I found it may be a carbide out side deburr tool for 50$!!!!

My issue comes with soft necks and the dullness of the "fins" of the starship style tools. There always seems be something there I can hang a thumb nail on. It aint smooth! Then with annealed cases if ya push AT ALL ya ruin the case...

Is this RCBS tool "worth it"?

CW

I have use "spaceships" and the LEE and Lyman tools for years as well.

The lee is actually nicest if it was just a bit more agressive.

I was looking thru a fellas stuff last few days. (Sorting out for sale) and he had a Frankfort Arsenal case prep machine and a RCBS machine. The RCBS had a tool I had not seem. There was a Long tapered inside debur tool and a "cup looking" tool similar to that LEE but different. Searching I found it may be a carbide out side deburr tool for 50$!!!!

My issue comes with soft necks and the dullness of the "fins" of the starship style tools. There always seems be something there I can hang a thumb nail on. It aint smooth! Then with annealed cases if ya push AT ALL ya ruin the case...

Is this RCBS tool "worth it"?

CW