L1A1Rocker

Active Member

Well, it was time to parkerize the muzzle brake and barrel threads. So into the bead blasting cabinet went the brake. (I did not bead blast the threads) The after photo. . .

And then a good soaking in some Simple Green degreaser

Then into a hot water bath to clean off the degreaser and bring the part up to temp.

And then into the solution.

Say, did you know that parkerizing dissolves aluminum? A lot of people know that, but here's a cute point of trivia, it also dissolves Melonite. Yep, I found that out the hard way. . . more on that later.

Here's a short vid of the bubbling action.

And then into the cooling tank.

And then a good oiling to neutralize the parkerizing salts. And now I ran into a problems. Notic all that black on the paper towel? The park was wiping right off the brake.

And here you can see my beautiful two tone barrel - 1/2 Melonite, 1/2 Parkerized. And I have a partly parkerized brake with most of the park having wiped away.

Close up.

The next day Ian was to come over. He is graciously loaning me his wood fired smelter to melt down a few WW's I've got piling up. I showed him my beautiful barrel and he, like me, was concerned about the bore being part melonite and part parkerized. So I decided to try things again and drop the whole barrel in to strip off the rest of the melonite. I also decided to re-do the brake and made up some new solution to try.

Well the barrel came out "decent" but not great. You can still make out that it was done in two stages and just make out the line in the middle. But oiled up it's not bad, and of course it's hidden under a handgaurd. The brake??? Did the same darn thing!!!

After some discussion with Ian I was convinced to try again with a few changes. Ian believed that there was something on the surface of the brake that the Simple Green just wasn't getting off. (or the 4140 roundstock was mismarked and really some kind of metal that wouldn't take parkerizing) So I tried a third time changing two variables. I cleaned the brake with ether and added a LOT more concentrate to the solution.

Results were GREAT - it worked. God Bless Ian, he wound up babysitting the brake this last time while I was putting things away. He even did the messy job of oiling the brake afterword. THANK YOU IAN!

Now some pics.

Well, this barrel was for my second SBR and I decided to go ahead and assemble the upper today. But I ran into ANOTHER problem. I've been amassing all the parts over the last year or so and have most everything I need. I buy things on sale and picked up a great buy on the upper. It's a PSA blemish that was only 40 bucks. But I forgot something, the parts kit needed for the stripped upper - DHO!

So I decided to just put this barrel on my other SBR sense it was disassembled anyway. I'm going to hae to eventually get a shim kit to get the brake installed correctly. But right now my silencer is not done so I can just use a crush washer to install it. Without further worderness, here it is.

Next up, shooting it. I anticipate that I'll have to open up the gas port a bit. The barrel was 10.5" long with a .093 gas port. Chopping it down to 7.5" I'll prolly need to open that up to around .104 or so. Stay tuned. . .

And then a good soaking in some Simple Green degreaser

Then into a hot water bath to clean off the degreaser and bring the part up to temp.

And then into the solution.

Say, did you know that parkerizing dissolves aluminum? A lot of people know that, but here's a cute point of trivia, it also dissolves Melonite. Yep, I found that out the hard way. . . more on that later.

Here's a short vid of the bubbling action.

And then into the cooling tank.

And then a good oiling to neutralize the parkerizing salts. And now I ran into a problems. Notic all that black on the paper towel? The park was wiping right off the brake.

And here you can see my beautiful two tone barrel - 1/2 Melonite, 1/2 Parkerized. And I have a partly parkerized brake with most of the park having wiped away.

Close up.

The next day Ian was to come over. He is graciously loaning me his wood fired smelter to melt down a few WW's I've got piling up. I showed him my beautiful barrel and he, like me, was concerned about the bore being part melonite and part parkerized. So I decided to try things again and drop the whole barrel in to strip off the rest of the melonite. I also decided to re-do the brake and made up some new solution to try.

Well the barrel came out "decent" but not great. You can still make out that it was done in two stages and just make out the line in the middle. But oiled up it's not bad, and of course it's hidden under a handgaurd. The brake??? Did the same darn thing!!!

After some discussion with Ian I was convinced to try again with a few changes. Ian believed that there was something on the surface of the brake that the Simple Green just wasn't getting off. (or the 4140 roundstock was mismarked and really some kind of metal that wouldn't take parkerizing) So I tried a third time changing two variables. I cleaned the brake with ether and added a LOT more concentrate to the solution.

Results were GREAT - it worked. God Bless Ian, he wound up babysitting the brake this last time while I was putting things away. He even did the messy job of oiling the brake afterword. THANK YOU IAN!

Now some pics.

Well, this barrel was for my second SBR and I decided to go ahead and assemble the upper today. But I ran into ANOTHER problem. I've been amassing all the parts over the last year or so and have most everything I need. I buy things on sale and picked up a great buy on the upper. It's a PSA blemish that was only 40 bucks. But I forgot something, the parts kit needed for the stripped upper - DHO!

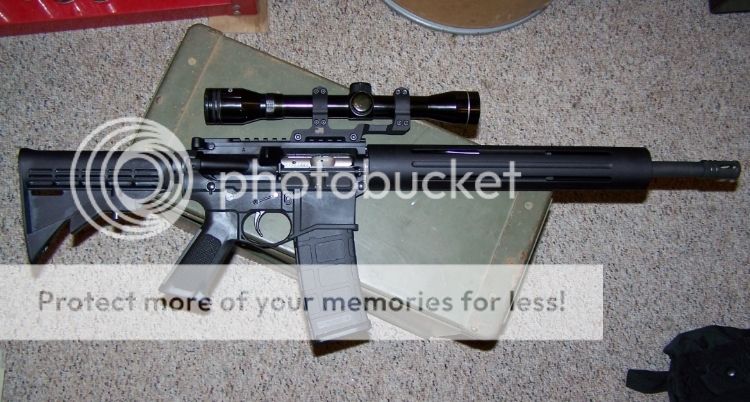

So I decided to just put this barrel on my other SBR sense it was disassembled anyway. I'm going to hae to eventually get a shim kit to get the brake installed correctly. But right now my silencer is not done so I can just use a crush washer to install it. Without further worderness, here it is.

Next up, shooting it. I anticipate that I'll have to open up the gas port a bit. The barrel was 10.5" long with a .093 gas port. Chopping it down to 7.5" I'll prolly need to open that up to around .104 or so. Stay tuned. . .

Last edited: