Everyone knows that Lee moulds are inexpensive.

Their quality control is " hit and miss " sometimes.

However, if you do manage to get a good one ( like I did recently ), a little bit of work can turn it into a real keeper.

As most of you know, the moulds regardless of caliber and design come with a sprue plate that is so tight that you'll mangle and ruin the tops of the mould blocks within the 1st hour of casting. The sprue plate ( on all that I've purchased recently ) had " saw teeth " on the edges of the sprue plate that had to be removed with a flat file. I have never been able to understand Lee's reasoning for tightening up the sprue bolt so tight ? ? ?

Obviously as soon as the mould arrives and before any damage is done to the tops of the mould blocks, you've got to reduce the pressure on the sprue plate.

Remove the sprue bolt and sprue plate ( be careful, the moulds made in the past 4 yrs. have reverse LH threads on the sprue hold down screw ).

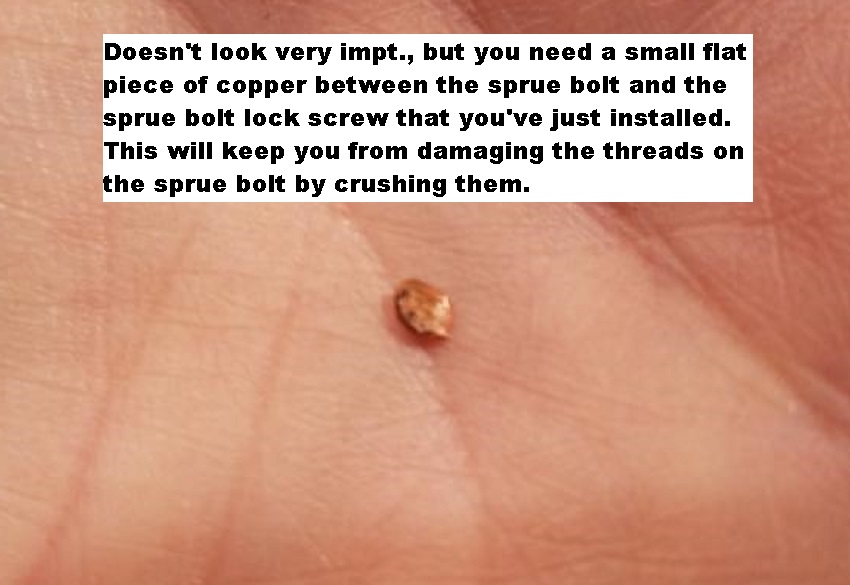

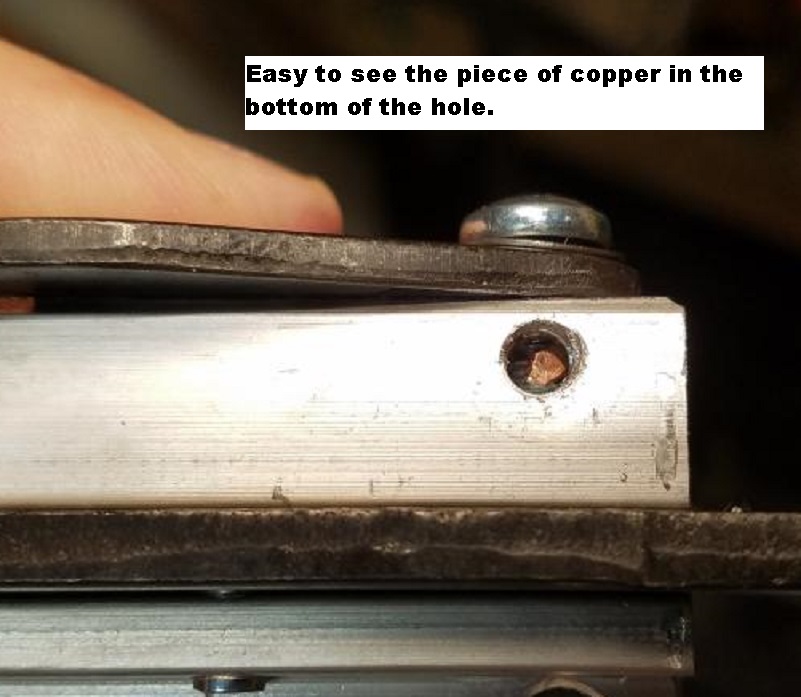

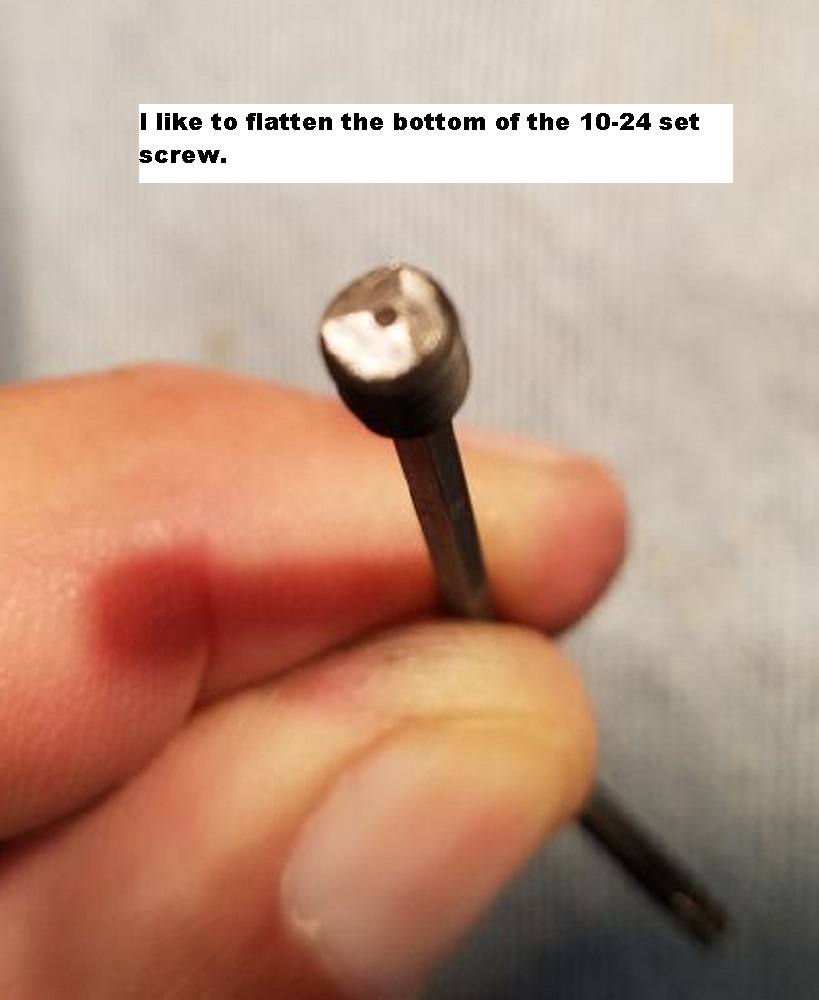

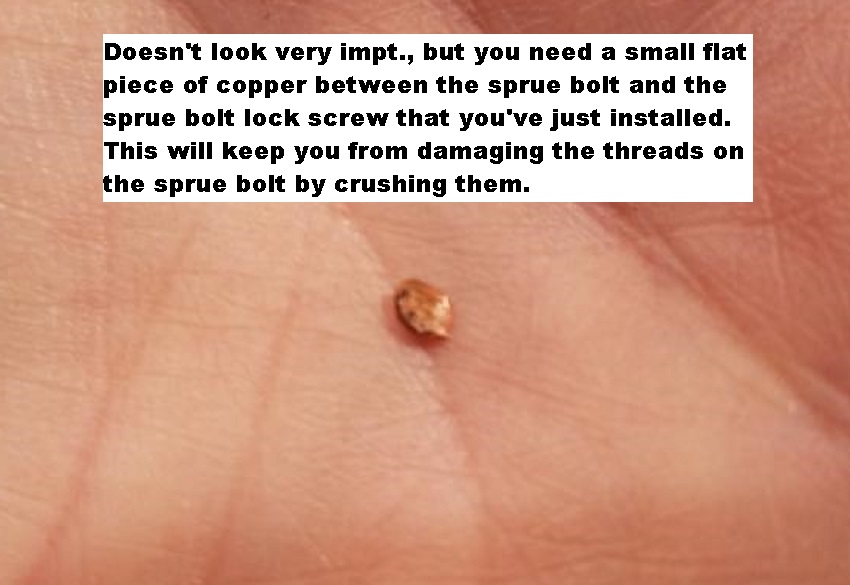

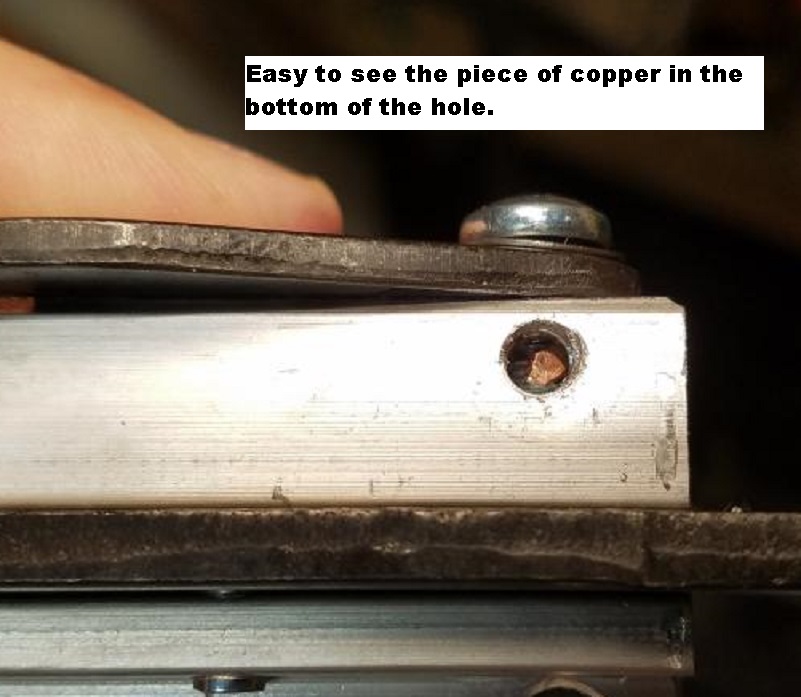

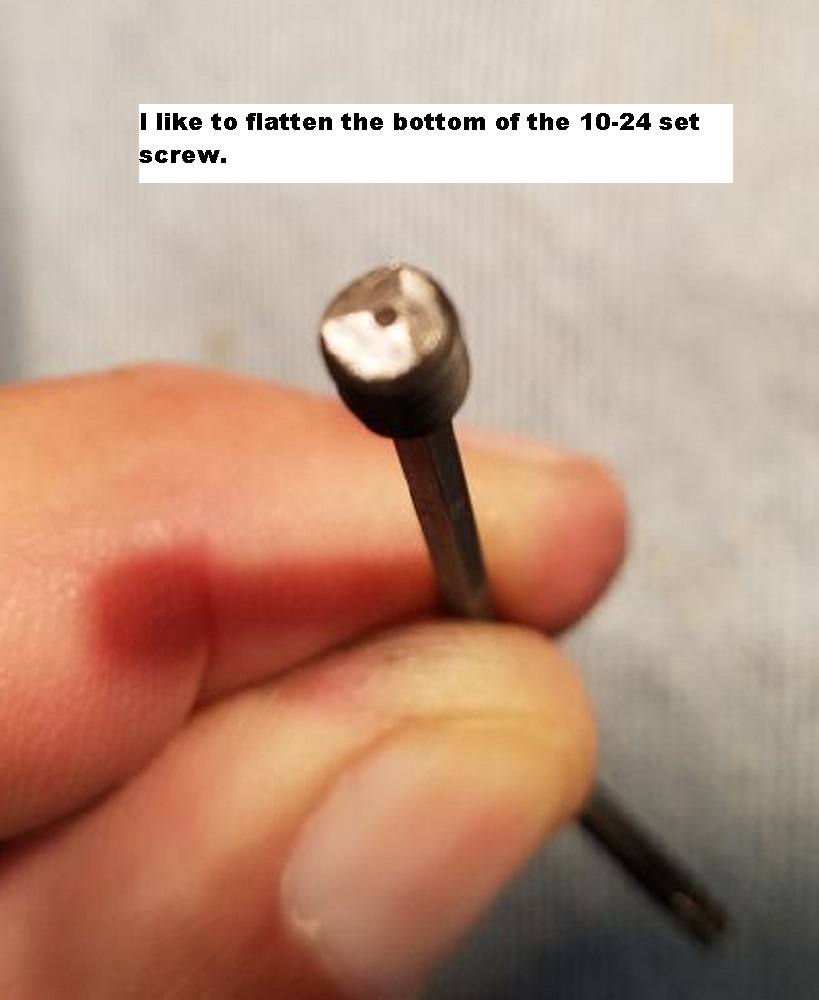

If you simply loosen the sprue plate screw only and do not install a set screw, the screw will " free wheel " while you're casting and the plate will become too loose. The answer to the problem is to drill the appropriate size hole in the mould and thread it for a set screw. I like to use Allen Head , 10-24 screws on Lee 2 cavity moulds. Works great. Here are a few pics that might help you understand the process.

Their quality control is " hit and miss " sometimes.

However, if you do manage to get a good one ( like I did recently ), a little bit of work can turn it into a real keeper.

As most of you know, the moulds regardless of caliber and design come with a sprue plate that is so tight that you'll mangle and ruin the tops of the mould blocks within the 1st hour of casting. The sprue plate ( on all that I've purchased recently ) had " saw teeth " on the edges of the sprue plate that had to be removed with a flat file. I have never been able to understand Lee's reasoning for tightening up the sprue bolt so tight ? ? ?

Obviously as soon as the mould arrives and before any damage is done to the tops of the mould blocks, you've got to reduce the pressure on the sprue plate.

Remove the sprue bolt and sprue plate ( be careful, the moulds made in the past 4 yrs. have reverse LH threads on the sprue hold down screw ).

If you simply loosen the sprue plate screw only and do not install a set screw, the screw will " free wheel " while you're casting and the plate will become too loose. The answer to the problem is to drill the appropriate size hole in the mould and thread it for a set screw. I like to use Allen Head , 10-24 screws on Lee 2 cavity moulds. Works great. Here are a few pics that might help you understand the process.

Last edited: