JWFilips

Well-Known Member

Hi Folks,

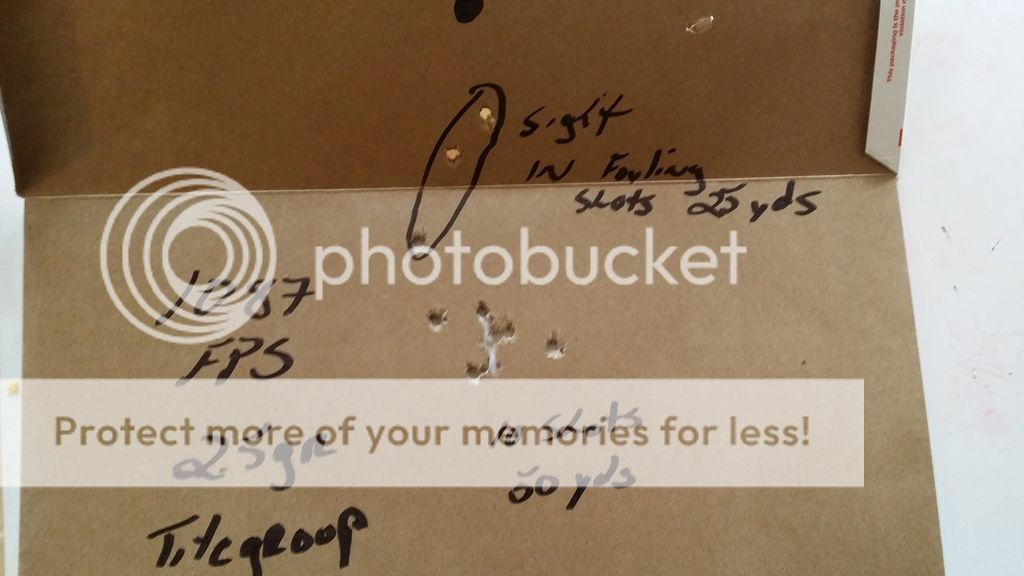

I'm shooting a .223 Rem in a Remington Sportsman 78. It is a super shooting rifle with cast but I found a bullet that perplexes me: It is a plain base NOE FN 55 grain which drops at 61.5 grains Plain base.

The 78 has a twist of 1 in 12....by doing the math does anyone know how slow I can shoot this bullet?

I can shoot the 62.5 Gas Checked version pretty well at 1900-2000 fps with 10 gr of 2400. Just can't seem to figure out were to start loading for a plain base version. Any loads I have tried in the 1600 to 1800 range turn into shotgun patterns with leading of the bore on a BHN 22 alloy

Jim

I'm shooting a .223 Rem in a Remington Sportsman 78. It is a super shooting rifle with cast but I found a bullet that perplexes me: It is a plain base NOE FN 55 grain which drops at 61.5 grains Plain base.

The 78 has a twist of 1 in 12....by doing the math does anyone know how slow I can shoot this bullet?

I can shoot the 62.5 Gas Checked version pretty well at 1900-2000 fps with 10 gr of 2400. Just can't seem to figure out were to start loading for a plain base version. Any loads I have tried in the 1600 to 1800 range turn into shotgun patterns with leading of the bore on a BHN 22 alloy

Jim