Cherokee

Medina, Ohio

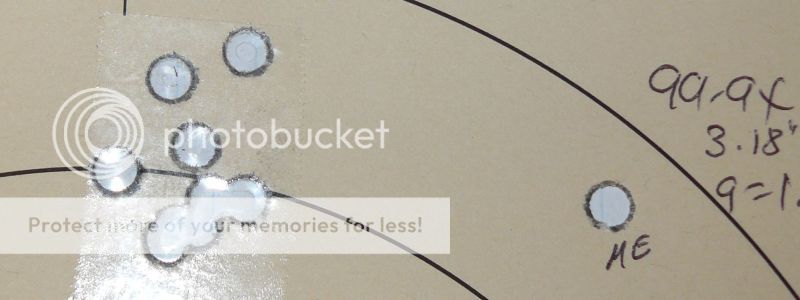

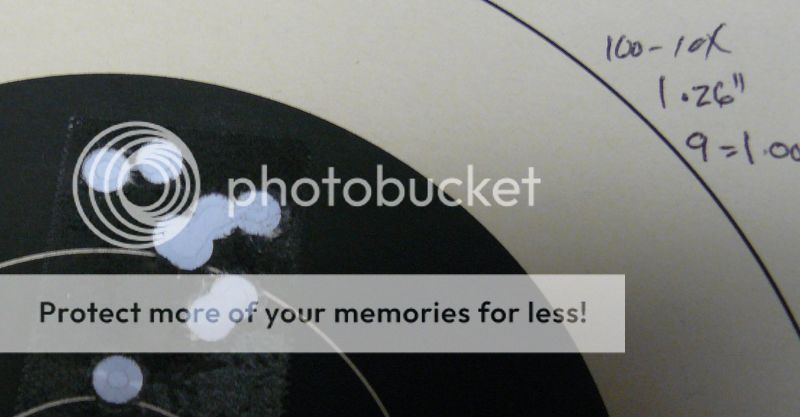

The other day I got my new 357135RF mold from NOE. After cleaning and a few heat/cool cycles, cast up a few 100 for initial test in 38 Special. From my 6" Model 15 S&W and 5" 686 S&W, they cut one large hole from a rest, not so small a group from my two hands but good for me. I'm going to have to try them in 357 Mag now that I know they will shoot.

I was a little concerned with the small shallow lube groove but got no leading from either gun.

I was a little concerned with the small shallow lube groove but got no leading from either gun.