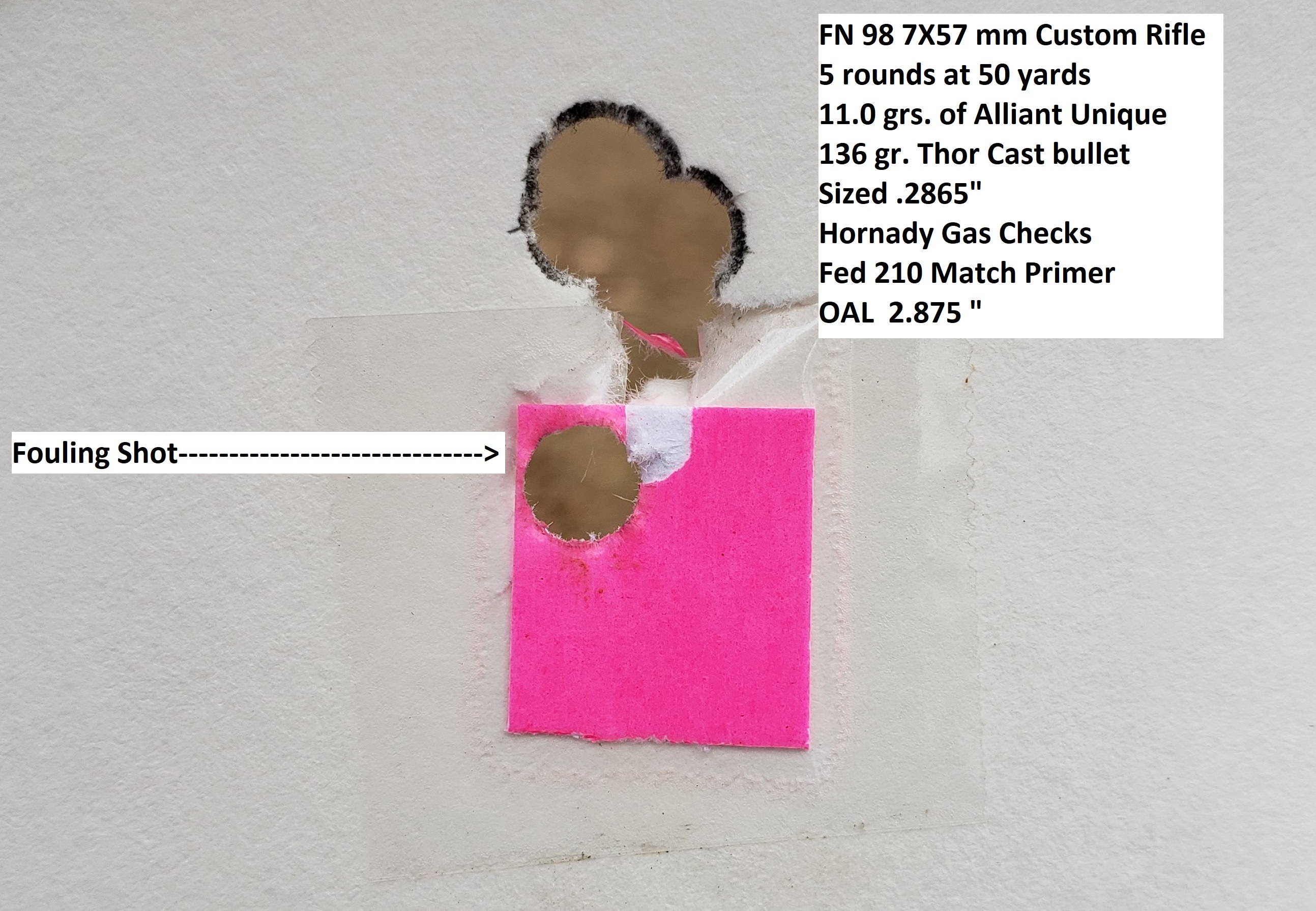

I finally had some good weather to go to the range today.

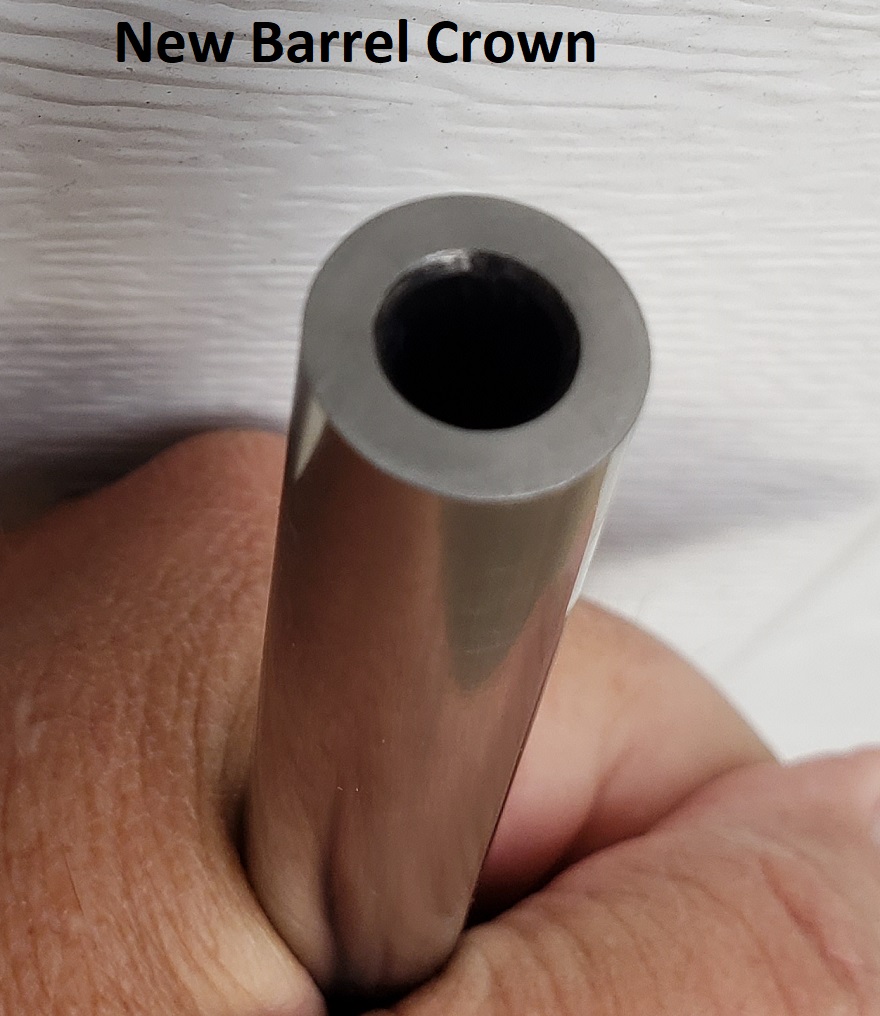

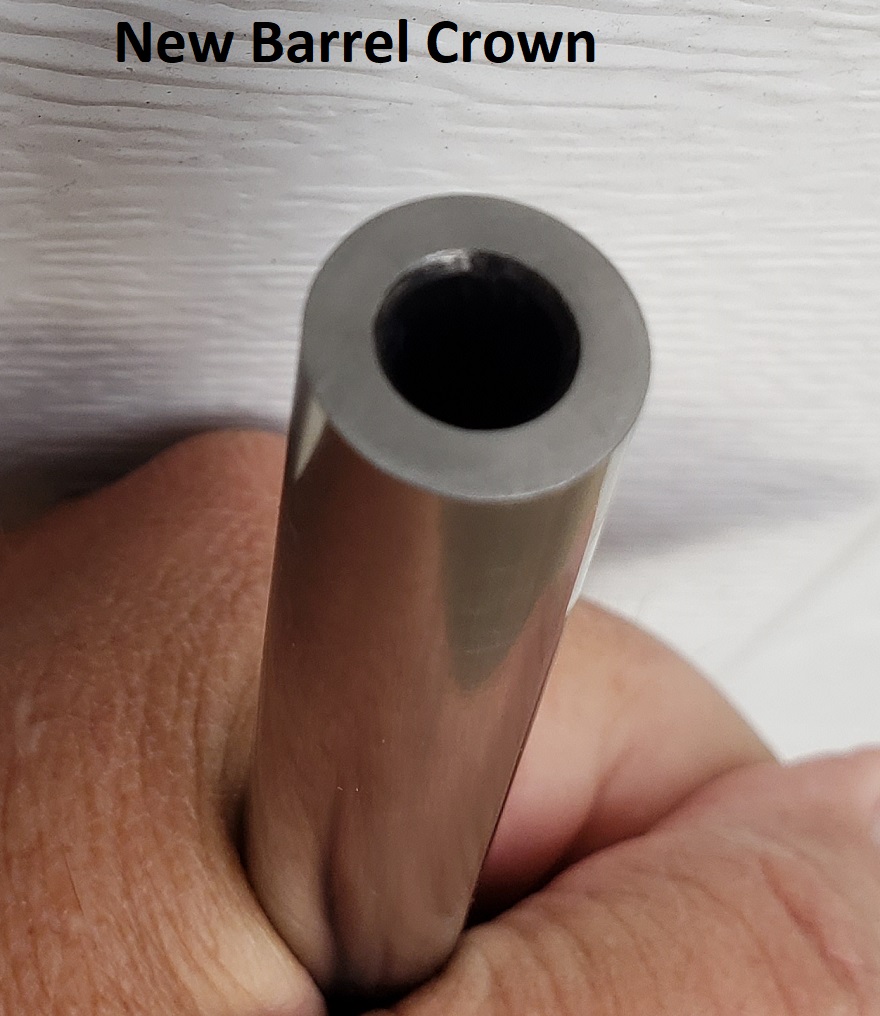

My last attempts ( 3 weeks ago ) with this rifle were a dismal failure . It shot all over the paper, after 10 rounds, I put the rifle back in the case and took it home. Didn't take too long to find the problem- - a bad barrel crown.

I took the 24" barrel and cut it back to 22" and re-crowned it.

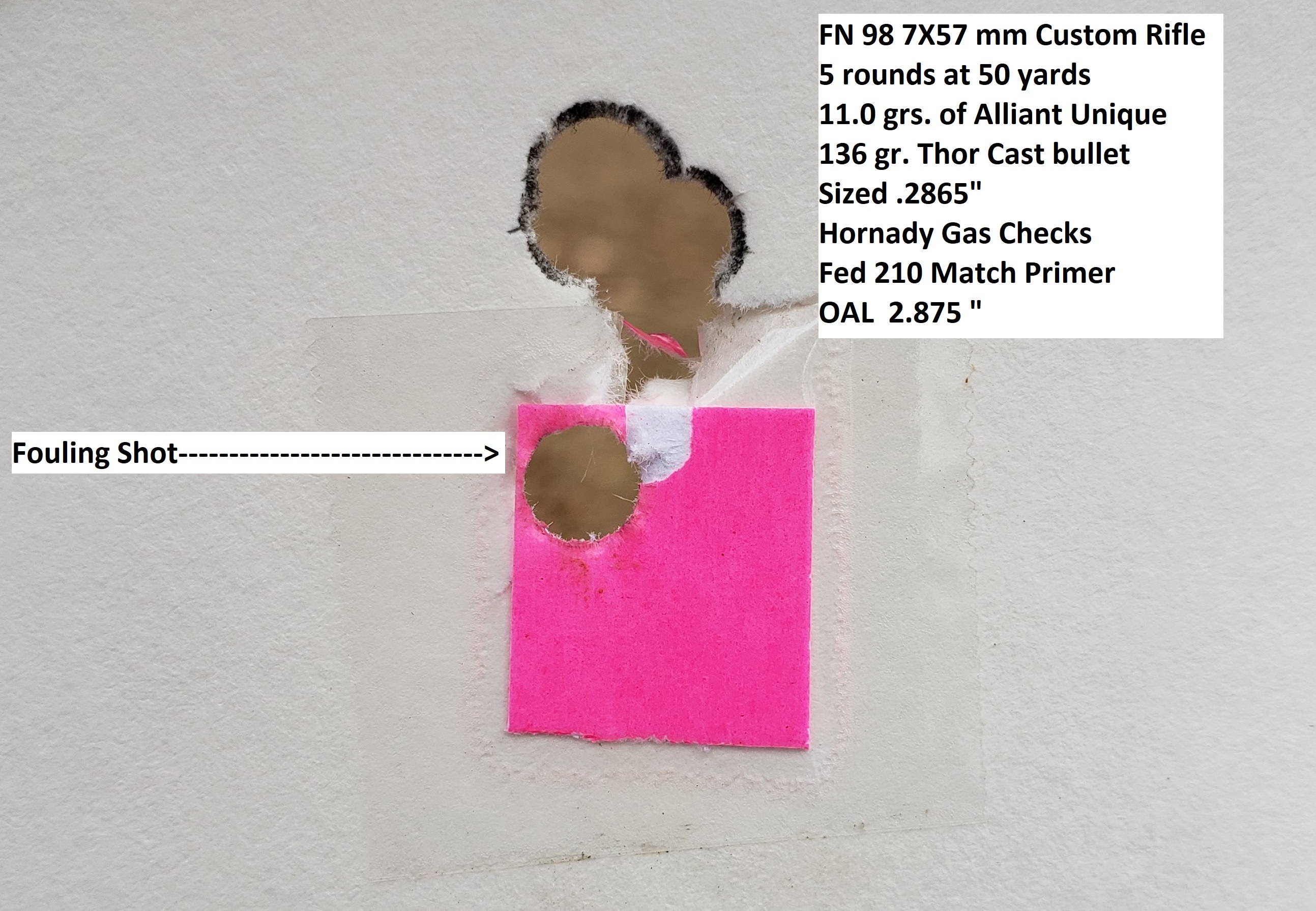

Today was my 1st opportunity to see if the re-crown fixed the accuracy problem.

I think the new crown fixed my earlier problem.

Ben

Here is the " Thor " bullet that you see in the group below.

Notice the clean holes it cuts in the target.

Would probably do that to flesh also.......

My last attempts ( 3 weeks ago ) with this rifle were a dismal failure . It shot all over the paper, after 10 rounds, I put the rifle back in the case and took it home. Didn't take too long to find the problem- - a bad barrel crown.

I took the 24" barrel and cut it back to 22" and re-crowned it.

Today was my 1st opportunity to see if the re-crown fixed the accuracy problem.

I think the new crown fixed my earlier problem.

Ben

Here is the " Thor " bullet that you see in the group below.

Notice the clean holes it cuts in the target.

Would probably do that to flesh also.......

Last edited: