Ian

Notorious member

462 generously passed on an RCBS

.45 rifle mould to me that had been beaten up in a few places by a previous owner. The top of the blocks had some big dents around the cavity which displaced metal into the gas check shank area and the corners of the cavity had a gap.

Since I was looking for a plain base mould of this caliber and weight design, the most sensible thing to do was to plain base it and face down the blocks a little to clean everything up.

Step the first was to drill a hole through the bottom part of the RH block so I could punch out the sprue plate stop pin.

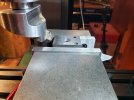

Next I checked the blocks for parallelism and set them up in the mill vise to check roundness. After indicating the base band on center with the spindle I found .002" oval so out they came for dressing. I couldn't get an accurate roundness measurement on the check shank due to damage and distortion so the only other way I had was to use the test indicator and sweep the cavity a little deeper inside.

I reinstalled the mould in the vise, trammed the face square, indicated on center with the base band just above the check shank, put in my boring head, and started making a scratch cut. Here's where it went off the rails. The cut was off center and cutting a weird arc inside the check shank. I stopped and pulled the blocks out of the vise to have a better look.

It looked as though the cavity wasn't square to the blocks so I set it up once again in the mill vise and trammed the face square to the spindle with the test indicator. Then I indicated the base band on center and then checked the nose band in front of the crimp groove. Turns out the cavity was crooked by .009"/2 along the parting line and .005"/2 perpendicular to it. I shimmed the mould with paper to fix it to within .001"/2 of straight up and down. I'm going to re-face the mould anyway, might as well make it square too. The second attempt at boring made clean, straight cuts that followed the check shank into the base band without any weirdness. I went ahead and bored it out about .002" larger than the other bands because like most RCBS moulds it's just a touch undersized for what I like.

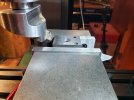

After cleaning out the check shank and base band, I switched gizmos and flycut the top of the blocks.

All done and back together, will try casting with it tomorrow or next week and see what I have.

.45 rifle mould to me that had been beaten up in a few places by a previous owner. The top of the blocks had some big dents around the cavity which displaced metal into the gas check shank area and the corners of the cavity had a gap.

Since I was looking for a plain base mould of this caliber and weight design, the most sensible thing to do was to plain base it and face down the blocks a little to clean everything up.

Step the first was to drill a hole through the bottom part of the RH block so I could punch out the sprue plate stop pin.

Next I checked the blocks for parallelism and set them up in the mill vise to check roundness. After indicating the base band on center with the spindle I found .002" oval so out they came for dressing. I couldn't get an accurate roundness measurement on the check shank due to damage and distortion so the only other way I had was to use the test indicator and sweep the cavity a little deeper inside.

I reinstalled the mould in the vise, trammed the face square, indicated on center with the base band just above the check shank, put in my boring head, and started making a scratch cut. Here's where it went off the rails. The cut was off center and cutting a weird arc inside the check shank. I stopped and pulled the blocks out of the vise to have a better look.

It looked as though the cavity wasn't square to the blocks so I set it up once again in the mill vise and trammed the face square to the spindle with the test indicator. Then I indicated the base band on center and then checked the nose band in front of the crimp groove. Turns out the cavity was crooked by .009"/2 along the parting line and .005"/2 perpendicular to it. I shimmed the mould with paper to fix it to within .001"/2 of straight up and down. I'm going to re-face the mould anyway, might as well make it square too. The second attempt at boring made clean, straight cuts that followed the check shank into the base band without any weirdness. I went ahead and bored it out about .002" larger than the other bands because like most RCBS moulds it's just a touch undersized for what I like.

After cleaning out the check shank and base band, I switched gizmos and flycut the top of the blocks.

All done and back together, will try casting with it tomorrow or next week and see what I have.

Last edited: