You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1968 Forester travel trailer project

- Thread starter Glaciers

- Start date

Petrol & Powder

Well-Known Member

I'm going to be the negative voice here, sorry.

The plan of marrying another frame rail under the existing rail will work but you're getting into a fairly big rebuild at that point. Plus, you're relying on the old thin/rusted rail now between the new rail and the trailer body. It's more of a patch than a repair.

As for the axle, yes you can switch that axle so that it sits under the springs and gain a little lift. Welding spring perches on the other side of the axle tube is easy and you may even be able to cut the current ones off and re-use them. However, it may be cheaper in the long run to simply replace that drop axle with a new complete straight axle. You'll gain the clearance you desire and get new brakes, bearings, spindles, etc. in the process.

Before I started buying parts, materials, welding frame rails and re-positioning axles, I would step back and make a seriously honest evaluation of the overall condition of the trailer.

I think the more problems you look for - the more you will find.

The plan of marrying another frame rail under the existing rail will work but you're getting into a fairly big rebuild at that point. Plus, you're relying on the old thin/rusted rail now between the new rail and the trailer body. It's more of a patch than a repair.

As for the axle, yes you can switch that axle so that it sits under the springs and gain a little lift. Welding spring perches on the other side of the axle tube is easy and you may even be able to cut the current ones off and re-use them. However, it may be cheaper in the long run to simply replace that drop axle with a new complete straight axle. You'll gain the clearance you desire and get new brakes, bearings, spindles, etc. in the process.

Before I started buying parts, materials, welding frame rails and re-positioning axles, I would step back and make a seriously honest evaluation of the overall condition of the trailer.

I think the more problems you look for - the more you will find.

Last edited:

Glaciers

Alaska Land of the Midnight Sun

I'm going to be the negative voice here, sorry.

The plan of marrying another frame rail under the existing rail will work but you're getting into a fairly big rebuild at that point. Plus, you're relying on the old thin/rusted rail now between the new rail and the trailer body. It's more of a patch than a repair.

As for the axle, yes you can switch that axle so that it sits under the springs and gain a little lift. Welding spring perches on the other side of the axle tube is easy and you may even be able to cut the current ones off and re-use them. However, it may be cheaper in the long run to simply replace that drop axle with a new complete straight axle. You'll gain the clearance you desire and get new brakes, bearings, spindles, etc. in the process.

Before I started buying parts, materials, welding frame rails and re-positioning axles, I would step back and make a seriously honest evaluation of the overall condition of the trailer.

I think the more problems you look for - the more you will find.

First off I appreciate a negative voice, it gets me questioning the project piecemeal and in its entirety. That’s exactly why I posted here so different view points would help me evaluate what I’m getting into. I’m naturally a optimistic person and have turned more then a few sows ears into if not a silk purse, the a useable bag. So criticism is needed to help me out.

First off I am capable of doing the entire job start to finish. But being able to step back and evaluate the end product is hard. Hard to see the forest for the trees.

What I’m looking for is a camper that is secure, dry and can be heated. If the fridge doesn’t work then there’s a cooler. I’m simply looking to be a step up from tent camping.

That being said, I have to do this cheap because I’m not real bucks up. I’ve looked at a lot of under $4000 travel trailers for sale up here and they all need work just to use.

This trailer has a good tight roof as testament to sitting out in the weather & snow load for all of the last 20 years not having any leaks. The 12 volt wiring has to be replaced, 110v system is very basic and in good shape, the plumbing system is ok, the tank is probably needing to be replaced. The furnace is an unknown at this point. The fridge looks to just need a gasket, the old one is so hard the door just won’t quite close as opposed to being sprung as I first thought. There’s a lot of work to be done if it’s going to be useable for sure. I’m not looking for a show piece here, just a usable camper.

You see I’m talking myself into it.

Yeah P&P I have replaced axels on travel trailers before and the thought was to just buy a new straight axel complete with new brakes. Slip in gain the height need for this country. But the old axel has to come out anyway so I’m want to assess the brakes and decide then. One idea I had, and I did this to a 1974 brand new tandem axel travel trailer was to flip the axels under they were straight axels and the existing spring perches were good just by rolling the axels over. Proceeded to drag it 4000 miles up here.

So I was thinking that 2 $10 spring perches could be simply laid on top of the axel and the clamping action of a new u-bolt assembly would hold the axel in place without welding. I don’t weld so I’d have to take it to a shop. The perches are a 180* radius so they would nest against the old ones. The brakes I will pull open today and see what’s there. I believe the axel is the cheap part. A replacement straight axel with brakes is close to $500. If I have to completely replace the brakes, backing plate and all on this axel, is about $200.

The frame on the other hand is my dilemma. Yes it’s rusty and crusty but it’s towable as is but a failure is in the future I’m sure. It’s not bent but moving from the house box forward. Joining a lower heavier box tube under just makes since to me. Challenge is going all the way back to the springs of the axel. On the drivers side that a piece of cake. The other side with having to remove that drop section is were I question the repair. This is only a 2,000 pound trailer so a piece of box tube, one piece with a correct angle for the hitch I believe will be more then strong enough. I was going to fish plate about 5 or 6 times in the length with 4” flat straps through bolted, no welding, for each side.

Ian

Notorious member

I meant the tongue flexing around and ripping the shell up at the front. That made me think the frame and floor/front wall are trying to separate at the front of the frame. The lightweight frame is usually just functioning as a big bracket to hold the hitch and axle to the shell, much of the strength/stiffness actually comes from the shell itself, so if your frame/tongue is flopping and flexing, investigate the front attachment points to the body/floor. Flimsy as it looks, the tongue and frame shouldn't need any additional reinforcement if all is in decent condition with no cracks. Maybe some cross-brace welds were popped when it jacknifed?

Last edited:

Glaciers

Alaska Land of the Midnight Sun

Yeah Ian I started looking into that and so far there looks to be some separation in the right front corner. The rest of the 2/3’s across the front looks to be solid. The gram rail with the slight gap is on the passenger side. The other side looks tight. But still needs more investigation.

There is a couple of small weld cracks on the passenger side with the front cross brace

So how about this idea.

First off it doesn’t look that bad.

What if I have a piece of 1/8 plate cut in the shape and size of the tongue from just behind the hitch to where the tongue frame joins the main frame. The edge on the outside of the of the frame could be broke or turned up a couple of inches. Through bolt. Could weld some angle in between the frame on the plate to stiffen it.

This morning it was 18 degrees inside my shop and it’s warming but still kinda cold on the creeper. And I’m 68 so getting up from the creeper takes some thought.

There is a couple of small weld cracks on the passenger side with the front cross brace

So how about this idea.

First off it doesn’t look that bad.

What if I have a piece of 1/8 plate cut in the shape and size of the tongue from just behind the hitch to where the tongue frame joins the main frame. The edge on the outside of the of the frame could be broke or turned up a couple of inches. Through bolt. Could weld some angle in between the frame on the plate to stiffen it.

This morning it was 18 degrees inside my shop and it’s warming but still kinda cold on the creeper. And I’m 68 so getting up from the creeper takes some thought.

Last edited:

Petrol & Powder

Well-Known Member

You can certainly move the axle under the springs and gain some lift. That will cost you some U-bolts, nuts, washers and two perches. However, you will still have 50+ year-old spindles and probably 50+ year-old bearings, seals, and brake hardware. That doesn’t necessarily mean those things will be bad, but it might be the beginning of a lot of little things that add up. If you get into that brake hardware and it looks like you will need a lot of parts, I would take a step back and think about the overall cost. Trailer bearings on a light trailer will last nearly forever IF maintained. They will fail quickly with near certainty if they have been neglected. You’ll have to make that call when you get the hubs off.

The fact that the body is not leaking is a testament to good original construction. It hasn’t lasted through 20 years of snow load & rain but rather 50+ years of weather. So, if the roof is tight, that’s a plus.

The frame is another story. If you have a corner of the body that is detached (sounds like from some prior damage), I would examine everything closely before I started investing time and money. The last thing you want to do is to get yourself into a “Sunk Cost Fallacy” situation. That is the tendency to invest more time or money because you’ve already invested and lost some time or money.

The fact that the body is not leaking is a testament to good original construction. It hasn’t lasted through 20 years of snow load & rain but rather 50+ years of weather. So, if the roof is tight, that’s a plus.

The frame is another story. If you have a corner of the body that is detached (sounds like from some prior damage), I would examine everything closely before I started investing time and money. The last thing you want to do is to get yourself into a “Sunk Cost Fallacy” situation. That is the tendency to invest more time or money because you’ve already invested and lost some time or money.

Petrol & Powder

Well-Known Member

I think that is a wise approach.

I can HIGHLY recommend using a pad of paper and a pen (perhaps a pencil will work better in your 18-degree shop ) to docuemnt needed repairs. Then start calculating costs BEFORE you start PAYING costs.

) to docuemnt needed repairs. Then start calculating costs BEFORE you start PAYING costs.

Inspect and assess before you spend.

I can HIGHLY recommend using a pad of paper and a pen (perhaps a pencil will work better in your 18-degree shop

Inspect and assess before you spend.

Ian

Notorious member

Brakes and bearings are cheap, as long as the magnets are good. Make sure you can actually GET the parts, some of the old electric brake stuff is becoming obsolete. The axle flip is easy if you can find a good shop to do the welding work. A pair of new spring perches should cost about $10 and the old ones can be removed with a gas axe without concern. It will look kind of silly with a 6" lift but will sure not drag the tail or the tongue jack ever again.

Bracing the tongue with a plate may be a good idea, just consider that where you stiffen it may transfer flex to parts which weren't designed to flex....and that can lead to cracks and breaks. Rather than a solid plate which will stress the tongue to frame rail welds (at the 53" width mark), I'd consider bolting some fish plates made of something like 2x3 angle inside the tongue from the hitch to the frame junction, notch and bend, and carry back about two more feet along the frame rails. Have the notches welded closed once bent and fitted and bolt a few lightweight cross braces as you drew above, just bolt to the horizontal flange of the angle iron fish plates. Bolting the braces and fish plates rather than welding will stiffen and strengthen the whole tongue and its connection to the frame with minimal risk of causing more cracks (as welding would do). I hope you have a good electric drill motor and drills!

Like I said before, my approach would be make sure it won't fall apart, make the electrical and plumbing sound, put some lipstick and mascara on it, and enjoy. Frame-off reconstructions are a younger man's game and if you're doing this just to use and not for its own sake, don't overthink the "restoration".

Bracing the tongue with a plate may be a good idea, just consider that where you stiffen it may transfer flex to parts which weren't designed to flex....and that can lead to cracks and breaks. Rather than a solid plate which will stress the tongue to frame rail welds (at the 53" width mark), I'd consider bolting some fish plates made of something like 2x3 angle inside the tongue from the hitch to the frame junction, notch and bend, and carry back about two more feet along the frame rails. Have the notches welded closed once bent and fitted and bolt a few lightweight cross braces as you drew above, just bolt to the horizontal flange of the angle iron fish plates. Bolting the braces and fish plates rather than welding will stiffen and strengthen the whole tongue and its connection to the frame with minimal risk of causing more cracks (as welding would do). I hope you have a good electric drill motor and drills!

Like I said before, my approach would be make sure it won't fall apart, make the electrical and plumbing sound, put some lipstick and mascara on it, and enjoy. Frame-off reconstructions are a younger man's game and if you're doing this just to use and not for its own sake, don't overthink the "restoration".

RicinYakima

High Steppes of Eastern Washington

Back when I was building off road Trials Motorcycle trailers, I found out that bolting would be better than welding when going up over mountain ridges and valleys. Welding to get and keep the frame shape, but bolting for strength without cracking.

RBHarter

West Central AR

Etrailer parts sells a whole electric brake set from the backing plate out to the dust cup including the hub and drum for about $60 a side , or did 5 yr ago . It was cheaper to buy 2 whole sets less hub/drums and run wire for them than to replace the surge brake master cylinder . Their catalogue descriptions are clear with enough information to remove 98% of the doubt about fits . I can't remember but I think they have "flip/axle over/under" kits as well with saddle plates and new bolts . Small shipping was at USPS FRB rates where possible .

I have no advice about the body attachment .

I have no advice about the body attachment .

fiver

Well-Known Member

i been looking at this and thinking on it some.

you might want to hold off on the frame stuff for right now, other than taking some measurements and making a drawing of what you have there.

then keeping an eye out for another trailer [even one that isn't a home on wheels, like a pickup bed trailer or the like] and cutting out what you need.

then removing your front piece and grafting in a new tow section and part of the frame to what you have there.

1-2 cross braces wouldn't hurt either.

but a good new chunk up front would make me feel a lot better.

you might want to hold off on the frame stuff for right now, other than taking some measurements and making a drawing of what you have there.

then keeping an eye out for another trailer [even one that isn't a home on wheels, like a pickup bed trailer or the like] and cutting out what you need.

then removing your front piece and grafting in a new tow section and part of the frame to what you have there.

1-2 cross braces wouldn't hurt either.

but a good new chunk up front would make me feel a lot better.

Glaciers

Alaska Land of the Midnight Sun

I actually have a 23 foot tandem axle travel trailer frame with a 2 5/16 hitch, the Forester has a 2” hitch. It’s about 5” wider which isn’t the problem, it’s the drop frame on the passenger side for the door that’s a problem. Was considering using this frame, which would require cutting out the drop section. The second frame nested under would support that section easily. But I don’t think that’s necessary, I believe that would be over kill.

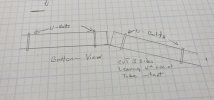

I’m going to pickup 2 pieces of 2x4 .185 wall box tubing. One piece 5’, the driver side 6’ long. Going to slice them at the junction where the tongue meets the frame. Cut through top, bottom and one side leaving one side intact. Make the bend to match the frame, 22.5 degrees. Using u-bolts to attach the 2 frames together, new under the original.

I will draw a picture of the parts as I probably not being very clear. But it’s simple, no welding, no cutting the original frame. Just support.

I’m going to pickup 2 pieces of 2x4 .185 wall box tubing. One piece 5’, the driver side 6’ long. Going to slice them at the junction where the tongue meets the frame. Cut through top, bottom and one side leaving one side intact. Make the bend to match the frame, 22.5 degrees. Using u-bolts to attach the 2 frames together, new under the original.

I will draw a picture of the parts as I probably not being very clear. But it’s simple, no welding, no cutting the original frame. Just support.

Glaciers

Alaska Land of the Midnight Sun

I also want to add that this is a trailer-camper for in-state Alaska use. Most trips are going to be 200 to 300 miles round trip at most. Maybe if we go to the coast, Valdez is a 750 mile round trip, or the Kenai of course certainly not in tourist season for the Kenai, that would be 1000 mile round trip.

So no Alcan trip to the lower 48. We keep an old class A in Washington state. That’s not to say that we have good roads in Alaska, because some really get serious frost heaves, but, I’m retired, not in a hurry.

So no Alcan trip to the lower 48. We keep an old class A in Washington state. That’s not to say that we have good roads in Alaska, because some really get serious frost heaves, but, I’m retired, not in a hurry.

Ian

Notorious member

Cut a pie piece out and fold it together instead of apart, then weld it together to make a solid tube and tack a patch of thin strap bent at 22.5⁰ on the inside to reinforce the seam. Slitting and bending outward will just tear the remaining flat side in two starting at the corners due to flex and won't add any significant stiffening to the tongue.

Your U-bolt attachment idea is terrific.

Your U-bolt attachment idea is terrific.

Mitty38

Well-Known Member

Lesson learned. I should never shoot a deer between two, 12 work days, in 55 degree weather.

Got off at five waited till 7 for daylight, Then went to sight in my muzzle loader this morning, was going to be a quick sight in, then go home to bed.

Had decided to go out for Black powder deer. Since I could not get time off right to make shotgun season worth while.

While sighting in the thing, felt I was being watched.

Turned around and there she was, 30 feet away a big beautiful doe. She must have weighed 200 lb, and me standing there with a loaded 50 caliber CVA.

Busted my hump fiield dressing it, then stopped by the Duke and Dutchess for 2 bags of Ice. Shoved them in the cavity, got it home, got the deep freeze set to 36 degrees.

Skinned and Quartered her in the truck bed deep woods style.

While wife picked up the bits and pieces and danced around the head, trying not to touch it while somewhat helping me.

So deer is very sloppily quartered, and siting in the deal freeze in garbage bags at a steady 36 degrees. Gun cleaned. Till I can finish butchering it out Saturday.

So do I get another permit or just forget about it, cause I have a full freezer.

But it's not really hunting to me if the deer looks for me to see who is blaring Hank and making all that noise shooting down there.Then she finds me and says "here I am on other firing range 30 ft from you, waiting patiently for you to kill me."

I am beat, tired, beat up and ready for bed but I have to leave for work in an hour.

Got off at five waited till 7 for daylight, Then went to sight in my muzzle loader this morning, was going to be a quick sight in, then go home to bed.

Had decided to go out for Black powder deer. Since I could not get time off right to make shotgun season worth while.

While sighting in the thing, felt I was being watched.

Turned around and there she was, 30 feet away a big beautiful doe. She must have weighed 200 lb, and me standing there with a loaded 50 caliber CVA.

Busted my hump fiield dressing it, then stopped by the Duke and Dutchess for 2 bags of Ice. Shoved them in the cavity, got it home, got the deep freeze set to 36 degrees.

Skinned and Quartered her in the truck bed deep woods style.

While wife picked up the bits and pieces and danced around the head, trying not to touch it while somewhat helping me.

So deer is very sloppily quartered, and siting in the deal freeze in garbage bags at a steady 36 degrees. Gun cleaned. Till I can finish butchering it out Saturday.

So do I get another permit or just forget about it, cause I have a full freezer.

But it's not really hunting to me if the deer looks for me to see who is blaring Hank and making all that noise shooting down there.Then she finds me and says "here I am on other firing range 30 ft from you, waiting patiently for you to kill me."

I am beat, tired, beat up and ready for bed but I have to leave for work in an hour.

Last edited: